App note: Level sensor & modulating ball valve maintain desired level in day tank

Mike Edwards

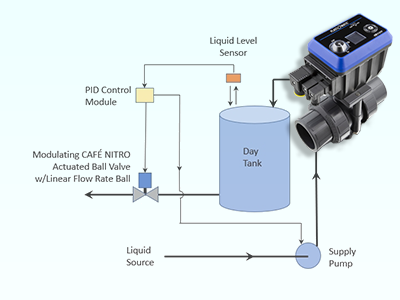

Features liquid level Plast-O-Matic Valves Sample schematic diagram for a level sensor & modulating ball valve maintaining a desired level in day tank. Inset: the Café Nitro actuated ball valve.

Sample schematic diagram for a level sensor & modulating ball valve maintaining a desired level in day tank. Inset: the Café Nitro actuated ball valve. Using an actuated ball valve in conjunction with a liquid level sensor and a PID control module will allow for very accurate level control within a storage tank. A storage tank can be kept at a constant fill level using an actuated Plast-O-Matic ball valve.

Placing the actuated valve downstream of the storage tank outlet allows for a controlled discharge. A level sensor is used to detect the height of the fluid in the storage tank.

The level sensor communicates to a PID control module that interprets the level sensor information and communicates to the actuated ball valve and the supply pump to open and close at a rate that is proportional to the demand on the tank. It also turns the pump on/off and controls the pump speed based on the demand.

The tank may have multiple taps to direct liquid where needed. Regardless of the demand on the tank, the control system will always keep the liquid level within the tank constant.

Liquid exiting the actuated ball valve can be directed back to the primary source, or to some other area of need.

The valve used for the application is the CAFÉ NITRO actuated ball valve, which includes programmable OLED screen, complete menus, fully directional keypad, and onboard diagnostics. For this application, the 4-20 mA or 0-10 VDC electronic control option was specified.

The valve itself is equipped with a SPECIALLY CHARACTERIZED BALL that provides increasing flow at a linear rate — versus a regular full port ball which is much harder to control.

For more information on the CAFÉ NITRO actuator from Plast-O-Matic, please click here.

Print this page