Applications of electrically operated double diaphragm pumps are now online

Mike Edwards

Features AODD pumps wastewater

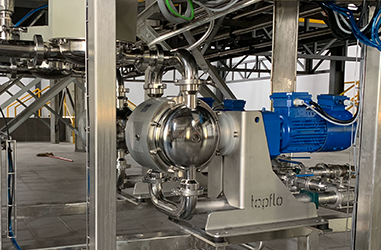

Recently introduced double diaphragm pumps, this time electrically operated (EODD), said to provide an eco-friendlier approach to the traditional AODD pump. One of the first EODD pumps put in operation was installed in April 2019 at a wastewater treatment facility since then pumping sludge with limescale.

The unit from Tapflo in this application has an electrically driven diaphragm pump with EPDM diaphragm, PE1000 valve balls and are built on frequency inverter.

The wastewater has a pH of 6 to 9, contains FeCl3, and is very abrasive. Particle size varies from 1 to 5 mm. The EODD pump operates at 50 Hz generating 90 l/min of flow at 1-1,5 bar. The pump runs 24/7 meaning it now has a runtime of over 9.000 h and has done more than 185 million strokes. After a 6 month period, a maintenance check was conducted on the pump, and, only as a precaution, the diaphragms where replaced.

The Tapflo pumps (the customer ordered a second unit) have replaced a hose and progressive cavity pumps. The first one suffered spontaneous hose raptures every 3-6 months and the other one required a stator replacement every 2-3 months.

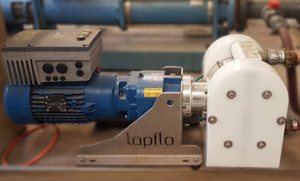

In another application (top), a customer was pumping latex and the required duty point was about 20 l/min @ 0.6 bar discharge pressure. This time, the system required a sanitary electrically driven diaphragm pump with FKM diaphragm and PTFE valve balls, bigger reducer.

The customer was using a competitor’s AODD pump but due to rapid diaphragm movement in a conventional pump, it experienced unwanted latex build-up inside the pump which led to blocking of the outlet. Tapflo selected an alternative pump but the latex polymerization was still too high. It was the time when we launched the EODD pump on the market.

At low frequency, it characterized with a much smoother operation between cycles. Deliberately Taplo oversized the pump to run it at low rpm (5 Hz ~6 rpm), as slow as possible, to ensure gentle product handling.

Both EODD pumps have successfully passed testing and commissioning and are now in operation since January 2020.

This article was contributed by Taplo.

Print this page