Avoiding bearing frame failure in food processing pump applications

Mike Edwards

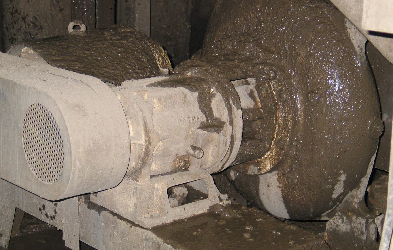

Features bearings isolators Significant contamination around this food processing pump challenged bearing life sue to constant material ingress.

Significant contamination around this food processing pump challenged bearing life sue to constant material ingress. Excessive contamination from the surrounding process and a leaking stuffing box can present a challenge in food and beverage applications. This scenario consistently caused premature bearing failure on a food processing pump, for example. The OEM rotary lip seals could not prevent contamination from entering the bearing housing, which caused catastrophic equipment failure in as little as a month.

The bearing frame failures would require shutdown of the process to remove and replace the frames, resulting in costly downtime.

Solution

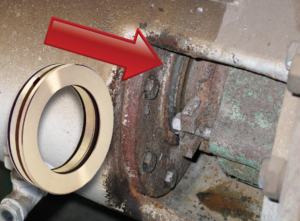

To solve this problem, Bearing Isolators from Inpro/Seal were installed on both ends of the bearing frame. The bearing isolator is a non-contacting bearing seal that permanently protects against contamination ingress and lubrication loss. Due to its non-contacting design, the bearing isolator has no wearing parts, and is said to last the lifetime of the equipment.

Watch video demonstration

Result

Bearing frame life increased to over two years and running in this application. Due to the increased performance on its pump bearing frames, the plant has targeted additional assets for Inpro/Seal Bearing Isolator upgrades, the company says.

An installed Inpro/Seal bearing isolator in service for multiple years still performing with no issue.

Permanent Bearing Protection

Inpro/Seal Bearing Isolators are also said to provide permanent bearing protection against contamination ingress and lubrication loss on a variety of rotating equipment.

This article was contributed by Inpro/Seal. Read More

Print this page