Blog: Avoiding manual data entry errors

Mike Edwards

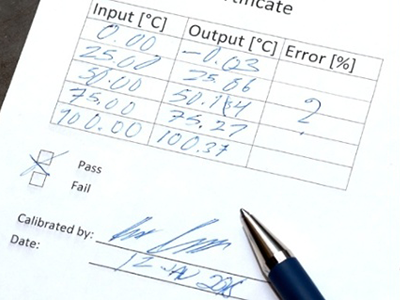

Features Beamex An example where the calibration data has been entered manually on a paper form. Possibly some numbers have been entered incorrectly, it is difficult to read some of them, manual error calculation is difficult, is that tick a pass or a fail, who signed that, and so on.

An example where the calibration data has been entered manually on a paper form. Possibly some numbers have been entered incorrectly, it is difficult to read some of them, manual error calculation is difficult, is that tick a pass or a fail, who signed that, and so on. Many businesses still use a lot of manual entry in their industrial processes. This is despite the fact that it is commonly known and accepted that it is a slow and labor-intensive process and there are always human errors related to manual data entry — human errors are natural.

It is commonly accepted that the typical error rate in manual data entry is about 1%.

What does this 1% mean in practice in calibration processes, and how can you make it smaller, or even get rid of it?

To start with, let’s take a look at the common ways in which data is handled in industrial calibration processes:

1. Pen & paper

2. Manual entry into a calibration system

3. Electronic storing of data

It is obvious that there are errors in manual data entry. It seems to be a commonly accepted rule that in manual data entry, human errors will cause a 1% average error rate.

This blog post by Beamex mainly focuses on industrial calibration processes and the manual data entry related to these processes. Continue reading here.

Print this page