Blog: How filtration can help steam applications

By Pall Corporation

Features applications blog filtration Pall Corporation plant steam

Steam is a basic but very important utility used in food and beverage plants. It enables a multitude of operations and processes which are integral to food production.

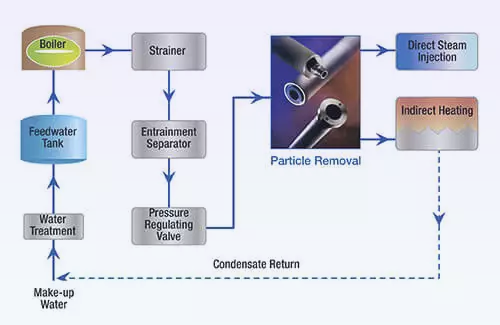

Steam is sterile, as its high heat kills viable microorganisms. However, there are other aspects of steam quality that have detrimental effects on food quality and manufacturing efficiency. Steam quality is influenced by boiler feedwater quality, the steam-generating method and equipment, and the steam distribution network.

Depending on the application, there are three key quality aspects of steam to address:

- presence of steam condensate,

- boiler feed water additives

- physical impurities such as rust, pipe scale, and other debris.

Removing large slugs of steam condensate from pipelines prevents water hammers that can create shock waves and damage the distribution network. Removing condensate from steam is necessary for product heating or cleaning applications, as the most efficient microbial kill is achieved with dry or saturated steam.

Some steam cleaning applications require dry steam to ensure efficiency, enable quick drying of cleaned equipment or introduce as little moisture as possible to water-sensitive dry products manufacturing facilities.

Some steam cleaning applications require dry steam to ensure efficiency, enable quick drying of cleaned equipment or introduce as little moisture as possible to water-sensitive dry products manufacturing facilities.

Controlling the liquid water content in steam is necessary; it is carried out by combining system design, managing the steam flow and pressure, and use of entrainment separators, steam traps, and other mitigation techniques.

Boiler feedwater is commonly treated with chemicals to prevent corrosion and scale build-up in the steam system. Any chemicals which are volatile and therefore carried over into the steam must be compatible and safe for the end-use application. In product contact applications, these chemicals must comply with regulatory requirements for human consumption.

Physical impurities in steam must be removed by filtration closest to the endpoint of use to prevent:

- compromising food product safety and sensory quality

- causing equipment fouling or plugging, resulting in reduced manufacturing efficiency and downtime.

The required filtration is dependent on whether the end-use involves a non-product contact application or direct steam contact with food products, or product-contact surfaces.

Print this page