Case Study: Thermal flow switch helps biogas storage tank’s safety valve to do its job

By Fluid Components International

Features biogas FCI FLT93 Fluid Components International tank safety thermal flow switch

At a large wastewater treatment facility, a newly installed digester gas storage tank required continuous monitoring of its safety valve for leakage to assure plant safety.

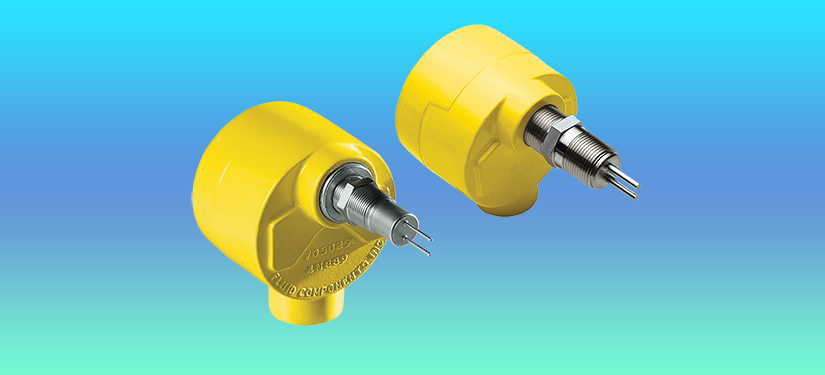

The plant’s operations and engineering team in charge of the tank project’s specification called for an ultra-reliable gas flow switch capable of detecting very low, slight leakage flow, as well as being certified for installation in a Zone 1 environment. The model FLT93 Flow Switch from Fluid Components International provided the solution to this demanding application.

Wastewater treatment digester processes produce large amounts of methane (CH4), a rich biogas that is used to produce energy and/or flared.

The resulting energy is often utilized to operate a wastewater treatment plant in a combined heat and power (CHP) system and/or can be exported to the public power grid as electrical or natural gas. In large WWTP operations, with variable production, excess biogas may be collected and stored in an on-site tank.

The flow switch series is SIL-2 rated for installation in safety-rated applications. These switches have a proven track record of global installations in CH4 flaring, combined heat and power (CHP), and safety valve relief applications in numerous industries, including wastewater treatment plants, biogas plants, and landfills where CH4 is present.

The gas flow switch is ideal for wastewater treatment digester gas applications. Based on its no-moving parts design, there are no orifices to clog in dirty digester gas environments. It also offers global approval certifications for installation in Exd explosion-proof safety locations where combustible gases could be present.

The switch is also SIL-2 rated for installation in safety-rated applications. These switches have a proven track record of global installations in CH4 flaring, combined heat and power (CHP), and safety valve relief applications in numerous industries, including wastewater treatment plants, biogas plants, and landfills where CH4 is present.

The flow switch detects extremely low flow velocities as low as 0.8 smps (0.25 sfps), which alerts plant operators to a leak incident or safety valve failure that compromises the safety system and gas storage or other processes. Instruments with no moving parts or small ports that can’t be fouled by particulates in the gas stream, such as the FCI model FLT93-F, are preferred in these dirty gas applications where sticky particulates, such as H2S residue, may be entrained in the gas and can clog or disrupt performance of other gas flow sensors that rely on orifices or mechanical movement.

When it is not economically feasible to remove water from the biogas, it is important to select an instrument such as the this flow switch, which is virtually unaffected by entrained moisture in the gas order to ensure measurement accuracy and repeatability, and with virtually no routine maintenance required.

The highly accurate and repeatable model FLT93F is ideal for use when these sensitive application environments are part of a safety instrumented system (SIS) requirement. This advanced, SIL 2 rated switch is specifically designed to meet safety applications where reliability of air/gas flow detection and is fast response to even very slight changes in the flow rate are paramount.

They are available in a variety of process connections for ease of installation in most any pipe, vent, or duct size. Its universal power supply supports powering by 115 Vac, 230 Vac, or 24 Vdc. Its trip-point/alarm points are easily user set in the field, at the installation. It comes with fail-safe, heavy-duty dual alarm (SPDT) or DPDT relay outputs, rated 6 A at 115 Vac, 240 Vac or 24 Vdc.

The flow switch’s flow sensor element is an all-welded design and constructed of premium 316L stainless steel. The instrument is available in a choice of aluminum or stainless steel enclosures that are NEMA 4X/IP66 rated. Electronics can be mounted integral with the flow element or remote mounted a distance away high temperature or excessive vibration type installations.

For applications in potentially explosive dust or gas environments, the FLT93F is also suitable for installation in Div 1/Zone 1 and Div 2/Zone 2 areas. It carries global certifications to standards of FM, FMc, ATEX, IECEx, NEPSI, EAC, Inmetro, UKCA, and EQM/ECAS. It also meets the EC directives for EMC and LVD and the flow element complies with Canadian Electrical code requirements of ANSI/ISA 12.27.01-2011 as a single seal device.

Print this page