Diagnostics: How do you know your pressure sensor is working as expected?

Mike Edwards

Features IO-Link pressure sensors video WIKA Canada The model A-1200 sensor from WIKA Canada has IO-Link communications capabilities to speed diagnostics.

The model A-1200 sensor from WIKA Canada has IO-Link communications capabilities to speed diagnostics. Determining if your pressure is functioning correctly at all times is critical to determine accurate measurements. Is the measuring instrument still working as it should? Pressure sensors with integrated diagnostic function and IO-Link provide information about their status at a glance.

What this means in detail can be illustrated using the example of the model A-1200 sensor from WIKA Canada.

The A-1200 is designed for use in industrial applications, especially for pressure measurement tasks in intelligent machinery. It features IO-Link for bidirectional data exchange. Via this channel, the instrument communicates the information from its diagnostic function to the master, which maps it for the control level.

Clear display

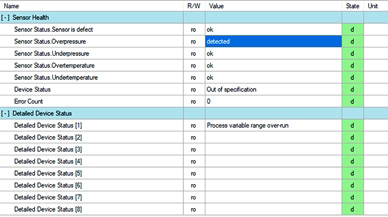

In this example, the sensor status is displayed in tabular form. Users can immediately and unequivocally see whether there is a defect or a discrepancy. The diagnostics function provides an overview of the status based on the following parameters:

- Sensor is faulty

- Overpressure

- Underpressure

- Overtemperature

- Undertemperature

With the A-1200 pressure sensor with diagnostic function and IO-Link, the user can obtain information about the status of the measuring instrument at a glance. The display format depends on the respective master.

Indication of changes in the process

If the diagnostic function detects overpressure or underpressure, the measuring instrument is operating outside its specifications. The A-1200 is an extremely robust product that can withstand overpressure, even over a longer period of time. An error message via IO-Link does not necessarily have to be related to a sensor defect. Rather, it also draws the user’s attention to a possible change in the process conditions. This would otherwise only be noticed in the event of an actual sensor failure.

Temperature in sensor electronics

The data on temperature refer to measurements in the sensor electronics. Deviations from the specification can be caused, for example, by an increase in ambient temperature. This, in turn, could have negative effects on the correct detection of the process pressure or the service life of the instrument. The user is therefore warned in good time of serious consequences for the process and the sensor.

Watch video demonstration:

Additional information

In addition to the status description, the A-1200 records further information that is read out via IO-Link. Among other things, it records the minimum and maximum values of pressure and temperature since the sensor was commissioned. In the event of an overload, users can track its duration.

The instrument also has an operating-hours counter and displays the measured temperature of the electronics. The recordings are continuous. If an instrument reset is necessary, all parameters are overwritten following the restart.

This article was contributed by WIKA Canada.

Print this page