Facing the challenges of calibration in the process industry’s hazardous areas

Mike Edwards

Features ATEX Beamex calibrator explosion proof intrinsically safe MC6-Ex SRP control systems video The Beamex MC6 Ex intrinsically safe calibrator.

The Beamex MC6 Ex intrinsically safe calibrator. There are many things you need to be aware before you can go to a hazardous (Ex) area to perform calibrations. There are different levels of hazardous areas and also different levels of calibration equipment.

By Heikki Laurila

First, we look at some fundamental considerations, theory and history. Then we look at different techniques to make calibration equipment suitable for an Ex area.

What is a hazardous area?

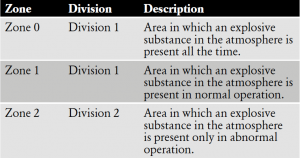

A hazardous area is an area (indoors or outdoors) that contains, or may contain, flammable substances. The flammable substance may be a liquid, gas, vapour or dust. Depending on the hazardous area classification, the area may contain a flammable substance all the time, or it is likely to be a certain ratio of the time, or only in specific situations, such as during shutdowns or accidents.

Play video for a demonstration.

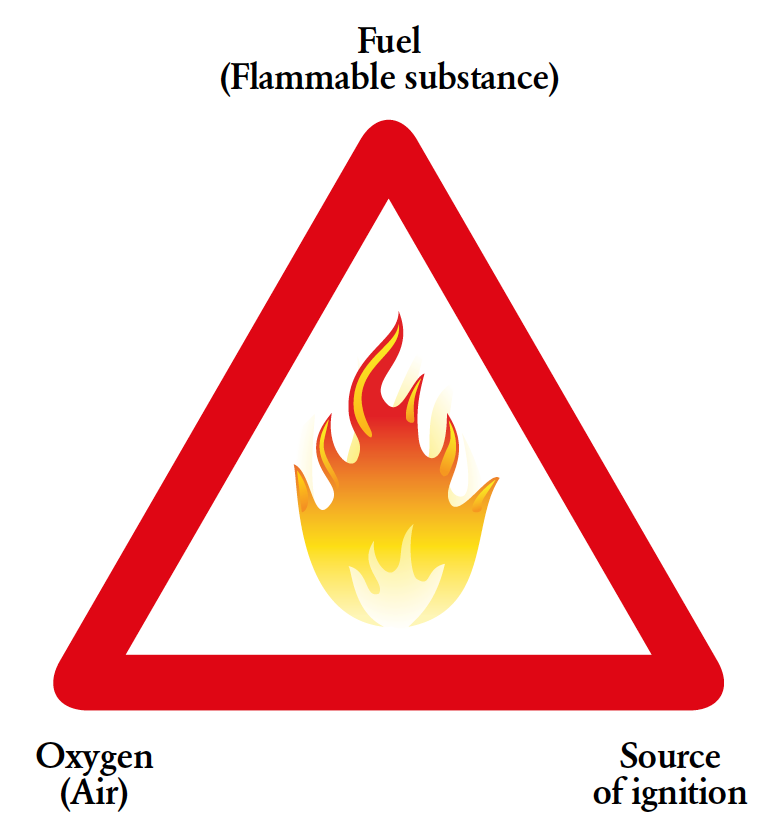

Explosion Triangle

In such a hazardous area, an explosion or fire is possible if all three conditions of the “Explosion Triangle” are met. These three conditions are fuel (a flammable substance), source of ignition (or heat) and oxygen (air).

In such a hazardous area, an explosion or fire is possible if all three conditions of the “Explosion Triangle” are met. These three conditions are fuel (a flammable substance), source of ignition (or heat) and oxygen (air).

The situation is often presented as a triangle; hence the name Explosion Triangle.

Eliminating one element from the explosion triangle

Keeping in mind the Explosion Triangle, we can conclude that one or more of the three elements must be eliminated, to make it safe. Many times, in an industrial application eliminating the flammable substance is not possible (you can’t eliminate fuel in a refinery), and therefore the oxygen (air) or source of ignition has to be eliminated.

However, it is also often very impractical or impossible to eliminate air. Therefore, the most practical solution is to eliminate the source of ignition, being spark or heat.

In the case of electrical calibration equipment, the device can be specially designed, so that it can be used safely in hazardous areas. There are many ways to design electrical equipment suitable for hazardous areas and this topic will be discussed later.

Calibration equipment is often designed in such a way that it cannot provide enough energy to cause the source of ignition, spark or heat.

Brief history of hazardous areas

Some of the first hazardous areas were discovered in early coal mines. Being flammable substances, both the coal dust and the methane absorbed created a hazardous area. The lighting in early mines was produced by candles and torches, generating a source of ignition.

This led to many accidents. Later, when miners began to use electrical equipment (lighting, tools), many accidents occurred due to sparking or heating. Eventually, design standards were developed to guide the design process to prevent the sparking and heating of electrical equipment.

This was the first “intrinsically safe” electrical equipment and it led the way to the standards compiled for equipment used in hazardous areas today.

Typical industries with hazardous areas

There are many industries that have hazardous areas. Some plants have large hazardous areas, while others have only small sections classified as hazardous areas. Typical industries with hazardous areas include chemical and petrochemical industries, offshore and on-shore oil and gas, oil refining, the pharmaceutical industry, food and beverage, energy production, paint shops and mining.

Since a flammable substance may be a liquid, gas, vapour or dust, there are surprisingly many different industries that may have some areas in the plant where these substances may be present during the normal operation or during shut-down. Even some seemingly safe industries may have hazardous areas.

Hazardous area logo

In plants, all areas classified as hazardous should be clearly marked with the Ex logo:

Flammable and combustible liquids

What are flammable and combustible liquids? Generally speaking, they are liquids that can burn. They may be gasoline, diesel fuel, solvents, cleaners, paints, chemicals, etc. Some of these liquids are present in many workplaces.

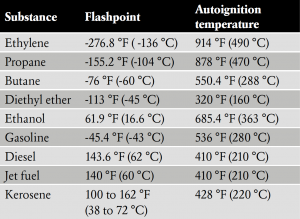

Flashpoint and autoignition temperatures are also often discussed.

Flashpoint is the lowest temperature of a liquid at which it produces sufficient vapor to form an ignitable mixture with air. With a spark or enough heat, it will ignite.

Autoignition temperature is the lowest temperature at which a liquid will ignite even without an external source of ignition. Most commonly, flammable and combustible liquids have autoignition temperatures in the range of 300° to 550°C. However, there are liquids that have an auto-ignition temperature as low as 200°C or less.

Based on their flashpoint, liquids are classified as flammable or combustible. Flammable liquids may ignite at normal working temperatures, while combustible liquids burn at higher temperatures. Often 100 °F (37.8 °C) is considered as the temperature limit.

Flammable liquids have a flashpoint below 100 °F and combustible liquids above. To be more precise, flammable and combustible liquids themselves do not burn, it is the vapors that burn. More precisely, it is the mixture of the vapors and air that burns.

There are also limits of the concentration within which the mixture can burn. If the concentration of the mixture is too low (too thin) it will not burn; the same is true if the concentration is too high (too rich). The limits are known as lower and upper explosive limits (LEL and UEL).

It is good to remember that some liquids may have a rather low flashpoint. For example, gasoline has a flashpoint as low as c. -40 °F (-40 °C). It produces enough vapors in normal environmental conditions to make a burnable mixture with air. Combustible liquids have a flashpoint way above normal environmental conditions, and therefore they have to be heated before they will ignite.

Some examples of flashpoints and autoignition temperatures:

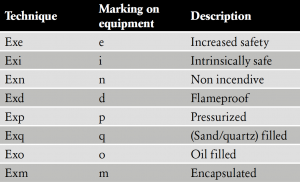

Various protection techniques

As mentioned earlier, to prevent an explosion, one of the three elements of the Explosion Triangle should be eliminated. In practice, eliminating the source of ignition would be the most sensible. There are various techniques in electrical equipment that make them safer for use in hazardous areas.

These different techniques fall into two main categories: eliminate the source of ignition (Exe, Exi) or isolate the source of ignition (Exd, Exp, Exq, Exo, Exm).

Intrinsically safe technique

The Exi “Intrinsically Safe” technique is the most commonly used and most suitable protective technique for electrical calibration equipment. Intrinsically safe equipment is designed so that it will not provide enough energy to generate sparks and excessively high surface temperatures, even in the case of a fault in the device. The equipment is designed to be intrinsically safe.

Inside an Exi device, the Exm (“Encapsulated”) technique may also be used for certain parts of the equipment (as in a battery pack).

“Hot work permit”

Using non-Ex calibration equipment in a hazardous area may be possible, but it requires special approval from the safety personnel in the factory. Oftentimes, this also involves the use of safety devices, such as personal portable gas detectors, to be carried in the field while working.

Using equipment rated for use in Ex area is easier, as it does not require any special approvals. Naturally, the rating of the Ex-rated calibration equipment must be suitable for the rating of the hazardous area to which it is taken to.

International/North American standards

There are two different standardizations specifying hazardous areas and classification of the equipment used in hazardous areas. One is the international IEC standard and the ATEX directive used in international and European legislation. The second is the North American legislation.

The international standard family of IEC 600779 defines the different standards for related regulations.

The IECEx scheme involves international cooperation based on the IEC standards. The objective of the IECEx system is to facilitate international trade in equipment and services for use in explosive atmospheres, while maintaining the required level of safety. Today, there are approximately 30-member countries in the IECEx, including Canada and the U.S.

The ATEX directive was introduced to unify hazardous equipment and work environments with the European Union. It was established about 10 years ago and is based on the directives of the 1990s.

Heikki Laurila is Product Marketing Manager at Beamex Oy Ab of Pietarsaari, Finland. Beamex is represented in Canada by SRP control systems. For more information, contact SRP control systems.

Print this page