Spreadable butter is one of the primary products of a Danish/Swedish dairy company in this case study where its facility is producing different brands for different markets. To be able to reproduce the specific characteristics of the different types exactly, ingredients must be precisely metered.

For ten years, the production facility has used LEWA pumps for this purpose, which are not only designed for high discharge pressures but also have an accuracy of ±1 percent, meeting the manufacturer’s strict requirements.

From the different variants of the ecoflow pumps, which are also very suitable for the production of food items, LEWA was able to configure an optimal solution.

Task

Water, rapeseed oil, and brine – those are the most important, exclusively natural ingredients to give the butter the company its medley salty flavour and its spreadable consistency. The mixing system for the plant must meet the strictest of hygienic requirements and – even more importantly – meter with high precision to ensure consistent product quality.

Since the entire production facility runs at a highly automated level for both hygiene and efficiency, the pumps must be able to work nearly maintenance-free, so that the process chain needs to be interrupted as little as possible. As salt has a corrosive effect over time, it was paid particular attention to the fact that the seals of the valves must remain elastic – even after years of contact with the brine.

Solution

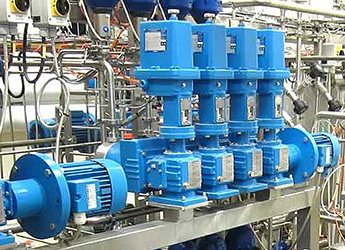

Since the ecoflow pumps from the Leonberg, Germany, manufacturer LEWA stand out not only for the fact that they are suitable for high discharge pressures, but also because they ensure good reproducibility, about thirty of them were installed in different production plants of this customer.

In line with the modular principle, different drives were combined, each with two to six pump heads. With the ecoflow, up to 6 m³/h per pump head can be conveyed, the metering accuracy is at ± 1 percent. The discharge pressure supported can reach up to 500 bar.

The pumps are easy to clean due to their small dead spaces. As sealing material Gylon was used, material of the diaphragms is PTFE.

The article was contributed by the Star Pump Alliance.

Print this page