By John Stoneback / JM Performance Products, Inc.

Titanium, stainless steel, aluminum, and other superalloys/exotic materials are on the rise for component manufacturing in vital growth industries such as aerospace, medical, and automotive. This creates a unique set of production machining challenges when considering that high speeds typically in excess of 20,000 RPMs are often required.

At these rates of speed, vibration and chatter can occur – leading to poor surface finishes that require secondary bench operations or result in critical damage to expensive workpieces.

Additional factors such as the lack of balance/concentricity of the toolholder, as well as improper seating within the spindle, can slow down machining cycle times–dramatically reducing material removal rates and the time it takes to complete each part from start to finish.

For these industries, in which cycle times are directly related to operational costs and the ability to provide competitive bids, adopting advanced technologies to decrease machining time is paramount to gaining a competitive edge. Progressive techniques for machining exotic materials effectively are evolving and available, however few shops effectively leverage them for milling these metals for optimal productivity.

Stability is the essential factor for adopting methods for improving milling performance on demanding materials like titanium–as the entire machining process has to be considered. Any one element could impede the overall process’s effectiveness as the tool, toolholder, spindle, column, ways, table, fixturing, and workpiece are all part of the interconnected ‘machining circle’ that require stability to achieve optimal results.

One stabilizing factor in achieving this “perfect circle” is a properly balanced toolholder in the spindle. At the rates of speed required for exotic metals, even minor flaws in toolholder fit or concentricity can lead to less- precise machining, reduced tool / spindle life, and even damaged workpieces.

Titanium, stainless steel, aluminum, and other superalloys/exotic materials are on the rise for component manufacturing in vital growth industries such as aerospace, medical, and automotive. This creates a unique set of production machining challenges when considering that high speeds typically in excess of 20,000 RPMs are often required.

At these rates of speed, vibration and chatter can occur – leading to poor surface finishes that require secondary bench operations or result in critical damage to expensive workpieces.

Additional factors such as the lack of balance/concentricity of the toolholder, as well as improper seating within the spindle, can slow down machining cycle times–dramatically reducing material removal rates and the time it takes to complete each part from start to finish.

For these industries, in which cycle times are directly related to operational costs and the ability to provide competitive bids, adopting advanced technologies to decrease machining time is paramount to gaining a competitive edge. Progressive techniques for machining exotic materials effectively are evolving and available, however few shops effectively leverage them for milling these metals for optimal productivity.

Stability is the essential factor for adopting methods for improving milling performance on demanding materials like titanium–as the entire machining process has to be considered. Any one element could impede the overall process’s effectiveness as the tool, toolholder, spindle, column, ways, table, fixturing, and workpiece are all part of the interconnected ‘machining circle’ that require stability to achieve optimal results.

One stabilizing factor in achieving this “perfect circle” is a properly balanced toolholder in the spindle. At the rates of speed required for exotic metals, even minor flaws in toolholder fit or concentricity can lead to less- precise machining, reduced tool / spindle life, and even damaged workpieces.

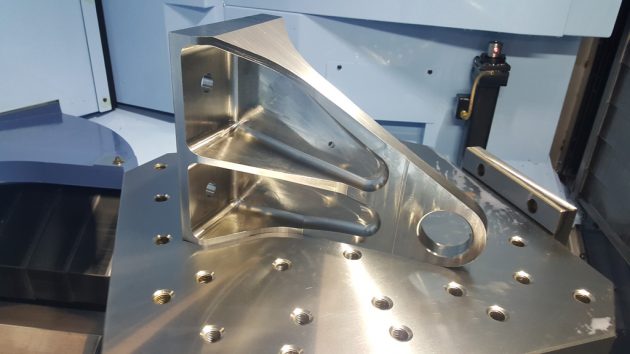

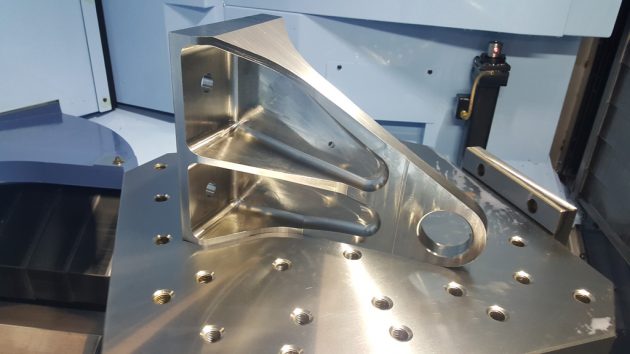

Recently, Delta Machine Company, LLC. – a company that specializes in titanium machining for the aerospace and the medical industries – addressed these issues by implementing JM Performance Products’ patented High Torque retention knobs.

Significantly higher drawbar pressure exerted on the retention knobs makes eliminating any issues with the interface between the toolholder and spindle of critical importance.

With a focus on high-speed machining of new exotic materials (80 per cent titanium, 15 per cent stainless steel, 5 per cent aluminum), Delta president Janos Garaczi wanted to get through roughing as fast as possible especially of titanium which took approximately 90 per cent of production time. Maximization of machining efficiencies enabling 24/7 production was critically important for key customer projects, such as:

• Boeing 737 MAX: The first new airplane of Boeing’s second century, advanced technology of the narrow-body aircraft series included a switch from composite to titanium on key portions of the design. Production of the series quickly set an industry record for the fastest introduction ever of a new jet transport, therefore, timely production and delivery by Delta was essential.

• Tesla: Type 17-4PH is a martensitic precipitation-hardening stainless steel that provides an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600 °F (316 °C). Delta predominantly used this material for very intricate Tesla product applications that required high strength and a modest level of corrosion resistance.

• Chevrolet: Highly polished, lightweight, corrosion resistant, premium 316L stainless steel was used by Delta in production of exhaust valves for Chevy.

Standard, off-the-shelf retention knobs could be used on Delta’s new machines, but Garaczi wanted to avoid scenarios where the machine’s high torque could shear off or break the retention knob and destroy the spindle – with replacement spindles running upwards of $40,000 or more to replace, not including the cost of any downtime.

“For the aggressive types of machining we do,” says Garaczi, “if you have a really strong retention knob, it’s going to further increase the rigidity of your set-up.”

To further maximize the rigidity and minimize vibration, Garaczi specified that Delta’s machines have dual contact spindles. In this configuration, both the toolholder shank (taper) and the flange are used to eliminate pull-back in the spindle.

To address these issues, Garaczi investigated a recommendation from one of his machine suppliers that he convert to a specific high torque retention knob from leading manufacturing innovator of CNC mill spindle optimization products JM Performance Products.

“The combination of the unique high torque retention knobs, along with dual-contact spindles and a combination of high speed and conventional tool path approach, has decreased cycle times as much as 40–50 percent,” says Garaczi. “This also allows us to often outbid the competition for projects involving titanium.”

With a focus on high-speed machining of new exotic materials (80 per cent titanium, 15 per cent stainless steel, 5 per cent aluminum), Delta president Janos Garaczi wanted to get through roughing as fast as possible especially of titanium which took approximately 90 per cent of production time. Maximization of machining efficiencies enabling 24/7 production was critically important for key customer projects, such as:

• Boeing 737 MAX: The first new airplane of Boeing’s second century, advanced technology of the narrow-body aircraft series included a switch from composite to titanium on key portions of the design. Production of the series quickly set an industry record for the fastest introduction ever of a new jet transport, therefore, timely production and delivery by Delta was essential.

• Tesla: Type 17-4PH is a martensitic precipitation-hardening stainless steel that provides an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600 °F (316 °C). Delta predominantly used this material for very intricate Tesla product applications that required high strength and a modest level of corrosion resistance.

• Chevrolet: Highly polished, lightweight, corrosion resistant, premium 316L stainless steel was used by Delta in production of exhaust valves for Chevy.

Standard, off-the-shelf retention knobs could be used on Delta’s new machines, but Garaczi wanted to avoid scenarios where the machine’s high torque could shear off or break the retention knob and destroy the spindle – with replacement spindles running upwards of $40,000 or more to replace, not including the cost of any downtime.

“For the aggressive types of machining we do,” says Garaczi, “if you have a really strong retention knob, it’s going to further increase the rigidity of your set-up.”

To further maximize the rigidity and minimize vibration, Garaczi specified that Delta’s machines have dual contact spindles. In this configuration, both the toolholder shank (taper) and the flange are used to eliminate pull-back in the spindle.

To address these issues, Garaczi investigated a recommendation from one of his machine suppliers that he convert to a specific high torque retention knob from leading manufacturing innovator of CNC mill spindle optimization products JM Performance Products.

“The combination of the unique high torque retention knobs, along with dual-contact spindles and a combination of high speed and conventional tool path approach, has decreased cycle times as much as 40–50 percent,” says Garaczi. “This also allows us to often outbid the competition for projects involving titanium.”

More than most industries, aerospace, medical, and automotive component manufacturing that machines a lot of exotic alloys and hard metals can take a toll on the carbide cutting tools used. The result is that the tools must be changed out more frequently as they dull or break. The cost of tool replacement, not to mention loss of production time due to frequent changeover, can escalate costs as well.

By using the unique high torque retention knob, Delta was able to resolve one of the most fundamental and long-standing problems in machining – improper seating of the toolholder in the spindle. Since tight tolerances are essential in high-speed machining, if the toolholder doesn’t fit the spindle precisely, decreased productivity and reduced tool life are inevitable.

An essential element of JMPP’s patented design is a knob that is longer and reaches deeper into the cross section of the holder’s threaded bore. As a result, all thread engagement occurs in a region of the toolholder where the cross-section is thicker to resist deformation. A precision pilot also increases rigidity. By increasing the rigidity of the toolholder at higher RPMs, the knob can increase tool life.

Implementing high torque knobs in the new high-RPM/high-torque equipment Delta installed resolved a key design flaw inherent in CNC v-flange tooling – eliminating the toolholder expansion responsible for costly CNC milling and boring issues. By increasing contact of the holder and the spindle at the gage line, a wide range of CNC milling issues are overcome including: vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, run-out, and shallow depths of cuts.

The product works with all existing V-Flange toolholders including: BT, DIN, ISO, and CAT toolholders from 30 to 60 taper. The solution provides V-flange toolholders with the rigidity and concentricity necessary for high- speed machining of titanium, aluminum, and other exotic metals/alloys, without having to turn to HSK or Capto tooling systems that are two- to three times more expensive.

By implementing over 800 of the high torque retention knobs, every tool on Delta’s machines works better and faster to make their demanding exotic materials projects more competitive and increase profit margins dramatically.

According to Garaczi, “At the end of the day, we are able to run titanium and stainless steel much faster than most machine shops that run about 50” per minute, with tool life typically reaching 1.5-2 hours before replacement. With the high- torque retention knob, we are running 150” per minute IPM in titanium and our tools last about 5 hours before we have to change them, which is pretty incredible.” Garaczi also noted the accuracy with the reduced runout (using the right tool holder and machine) which can interpolate 2” or any size bores with .0001” accuracy, with the ability to repeat it again and again in titanium.

By using the unique high torque retention knob, Delta was able to resolve one of the most fundamental and long-standing problems in machining – improper seating of the toolholder in the spindle. Since tight tolerances are essential in high-speed machining, if the toolholder doesn’t fit the spindle precisely, decreased productivity and reduced tool life are inevitable.

An essential element of JMPP’s patented design is a knob that is longer and reaches deeper into the cross section of the holder’s threaded bore. As a result, all thread engagement occurs in a region of the toolholder where the cross-section is thicker to resist deformation. A precision pilot also increases rigidity. By increasing the rigidity of the toolholder at higher RPMs, the knob can increase tool life.

Implementing high torque knobs in the new high-RPM/high-torque equipment Delta installed resolved a key design flaw inherent in CNC v-flange tooling – eliminating the toolholder expansion responsible for costly CNC milling and boring issues. By increasing contact of the holder and the spindle at the gage line, a wide range of CNC milling issues are overcome including: vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear and tear, run-out, and shallow depths of cuts.

The product works with all existing V-Flange toolholders including: BT, DIN, ISO, and CAT toolholders from 30 to 60 taper. The solution provides V-flange toolholders with the rigidity and concentricity necessary for high- speed machining of titanium, aluminum, and other exotic metals/alloys, without having to turn to HSK or Capto tooling systems that are two- to three times more expensive.

By implementing over 800 of the high torque retention knobs, every tool on Delta’s machines works better and faster to make their demanding exotic materials projects more competitive and increase profit margins dramatically.

According to Garaczi, “At the end of the day, we are able to run titanium and stainless steel much faster than most machine shops that run about 50” per minute, with tool life typically reaching 1.5-2 hours before replacement. With the high- torque retention knob, we are running 150” per minute IPM in titanium and our tools last about 5 hours before we have to change them, which is pretty incredible.” Garaczi also noted the accuracy with the reduced runout (using the right tool holder and machine) which can interpolate 2” or any size bores with .0001” accuracy, with the ability to repeat it again and again in titanium.

Another key advantage that Delta achieved was better surface finish – which eliminated additional benching operations that add to the cycle times.

“Usually at the feed rates and speeds that we run titanium, the typical finish expected is 125 (rms),” says Garaczi. “The high torque retention knob helps achieve a 50 rms finish at more than 100 in. per minute, which often exceeds what the customer requires.

“In the aerospace and medical industries, price is a factor, but the customer is more interested in top quality parts delivered on time.”

www.jmperformanceproducts.com

“Usually at the feed rates and speeds that we run titanium, the typical finish expected is 125 (rms),” says Garaczi. “The high torque retention knob helps achieve a 50 rms finish at more than 100 in. per minute, which often exceeds what the customer requires.

“In the aerospace and medical industries, price is a factor, but the customer is more interested in top quality parts delivered on time.”

www.jmperformanceproducts.com

Print this page

Advertisement

Stories continue below

Related