Load sensing by light fibre enables machine reliability

Mike Edwards

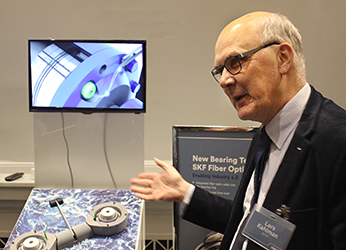

Features SKF Canada Lars Kahlman

Lars Kahlman Enabling radical improvements to machine reliability, SKF demonstrated its new optical sensing technology as part of the Sweden Co-Lab earlier this year at the Hannover Fair in Germany and more recently at the SKF Technical Press Day last month in Philadelphia.

SKF’s new sensing technology takes monitoring to the next level, providing engineers with new insights into machine performance. It has been field tested in subsea screw pump and marine thruster applications since 2008. SKF Fiber Optic Sensing uses optical fibres to measure forces, in real time, in difficult environments and without electronics.

The technology (see video above) provides an instant overview of equipment performance, measuring parameters such as load, speed and temperature. This opens up new opportunities for closed-loop control of processes. It also allows engineers to proactively prevent problems early. This can be unfavourable running conditions, misalignment or wear, before they lead to costly shutdowns.

Fibre optic sensing offers many advantages that makes it suitable for real industrial conditions. The technology uses light rather than electricity, which enables safe measurements in hazardous environments. The absence of electronics means the sensors are safe in electromagnetic fields. The fibres transmit light without disturbances at long distance (kilometres), which enables remote monitoring where wireless technology cannot be used.

According to Lars Kahlman, senior application expert and technical lead, SKF Fiber Optic Sensing Project, SKF Group, the company has partnered with Swedish telecom provider Hexatronic and customers to prove out the technology for several years. “A commercial launch in September is expected,” Kahlman told the press day meeting in Philadelphia presented by SKF USA.

He noted that the fibre optic sensing technology can be used in pump and compressor applications. Ex safety-rated, the technology is suitable for the oil and gas industry, resists liquids and enables online analysis and closed loop process control. “Designers can also create a digital twin with (companion) simulation software.”

Victoria van Camp, CTO AB SKF comments: “We (have) combined our specialist industrial knowledge with digital expertise from leading partners and customers. The result is a solution that reveals parts of a machine’s performance that were previously in the shadows, using the power of light alone.”

In Canada, contact SKF Canada.

Print this page