Taking Clamp-on Flow Measurement to a new level of performance with low cost of ownership

By By Vijay Acharya M.ENG, P.ENG

Features clamp on flow measurement ipptBuilding on decades of experience in manufacturing and supplying clamp-on flow meter technology globally combined with Digital innovation, Siemens SITRANS FS230 clamp-on flow system offers higher performance in demanding applications, improved user-friendliness, easier installation, and diagnostics for continuous reliable operation.

Siemens Ultrasonic clamp-on flow meters operate on “Transit Time” principle to accurately measure volumetric flow of liquids and gases in process industries such as municipal potable water, wastewater including sludge flow, district energy chilled, hot, and condensate water, oil and gas including hydrocarbon liquids, natural gas, hydrogen, LNG, chemical, power, food, and pharma. It is applied for density measurement for product identification and pig detection applications in oil pipelines transferring varieties of crude and finished products like gasoline, diesel, etc. of various producers.

NON-INTRUSIVE & NON-CONTACT

The clamp-on flow meter sensors are clamped on the outside surface of the pipe. When an electromagnetic flow meter cannot be applied, the clamp-on flow meter is the next best choice over other in-line flow technologies like vortex, Coriolis, thermal dispersion, differential pressure, turbine, variable area type flow meters.

- No moving parts, so it offers no obstruction or pressure drop, no wear and tear or fouling of wetted parts like electrodes of electro-magnetic flow meters.

- It is not affected by aggressive, corrosive, or toxic liquids or gases

- Contamination free when measuring the sterile or high-purity media.

- Independent of the pressure, temperature, and other fluid property variations.

EASY & PORTABLE

The clamp-on flow meters are easy to mount on the pipes15mm to 10M size without modifying or cutting the pipes or shutting down the process, this increases uptime and safety of the process and personnel.

- The portable clamp-on flowmeter is suitable to verify accuracy of other flow meters in the plant.

- Can be temporarily installed for flow survey or when the permanent flow meter has failed in the plant, and operators need flow information for monitoring and control of the processes until they replace/repair the failed flow meter.

DOPPLER OR TRANSIT TIME

Clamp-on ultrasonic flow meters are based on Doppler or on Transit Time of the liquid or gas. The Doppler effect example is a police car, as it moves closer to us the siren sounds louder and fades as it moves away, we call it a frequency shift. Doppler method is application sensitive and needs particles or bubbles in the fluid and due to various factors beyond scope of this article to discuss its accuracy can be as low as +/-20% or sometimes it ceases to work.

Siemens employs Transit Time principle for its Clamp-on Ultrasonic Flow meter SITANS FS230

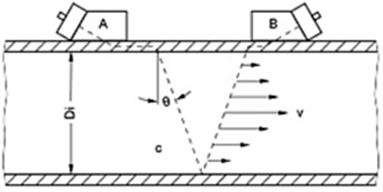

Figure 1: SITRANS FSS200 Sensors mounted in a reflect mode.

SITRANS FSS 200 clamp-on ultrasonic sensor pair A & B simultaneously transmits and receives acoustic signals directly through the pipe walls, where the refraction angle θ through the fluid is governed by Snell’s law of refraction.

Sinθ = C / Vϕ (C= speed of sound in fluid and Vϕ is phase velocity in pipe wall which is a constant).

The average transit time Tfluid of soundwaves in fluid between the sensors A and B is calculated by the meter by subtracting the computed fixed times within the transducers and pipe walls. The meter automatically compensates for the changes in sound velocity in fluid based on the variations in measured average transit time between sensors A and B.

The soundwaves travelling from sensor A to B (TA,B) in the direction of the flow arrives earlier than the soundwaves travelling from sensor B to A (TB,A) against the flow. This time difference ΔT is used to compute the integrated velocity(V) of the fluid as shown in the equation below.

V = (Vϕ/2) x (ΔT/Tfluid)

Once the fluid velocity is determined (V), the fluid Reynolds number is computed to apply correction factor (KRe) for fully developed profile. This requires entry of inside pipe diameter (Di), fluid dynamic viscosity (µ) and density (ᵨ). The volumetric flow rate (Q) is then calculated by using the following equation.

Q = (KRe) x (ỻ/4) x (Di)2 x V

Ultrasonic sensor types:

There are two types of SITRANS FSS200 sensors used with SITRANS FS230 clamp-on flow meter. Universal or Shear mode or narrow beam sensors are used for any sonically conductive pipe and selected based on outside diameter of the pipe. It injects an acoustic signal into the pipe wall, and effectively pushing the signal through the pipe and to the opposite sensor. This technology though is easier and less expensive, but susceptible to aeration and solids in the fluid. It is mainly employed for portable flow survey where accuracy of +/-1% to +/-2% is acceptable.

To read more articles like this, click here to download out Flow Measurement handbook.

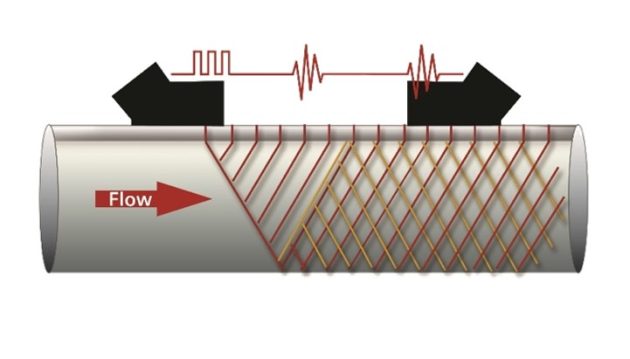

Siemens is a pioneer in lamb wave (wide beam) sensor technology. They are selected based on pipe wall thickness, it broadcasts a wide range of frequencies through the pipe and locates a frequency that matches close to the pipe wall. This frequency is transmitted through the fluid with pipe is acting as a wave guide this provide wide area of beam to optimize signal to noise ratio and improves measuring accuracy to +/-0.5% to +/-1% and tolerates aeration and solids particles in the fluid much better. Lamb wave or wide beam sensors uses lower energy and are designed for steel pipes but can also be used with Aluminum and Titanium pipes. The signals are more cohesive, prominent, and precise. As a result, we can mark the arrival of the receive signal with greater accuracy. By contrast, a one size fits all approach as does our competitor, it becomes necessary to “crank-up” the transmit amplitude to blast the signal through the pipe and as a result the signal suffers by arriving less pronounced and less precise.

Figure 2: Lamb wave wide beam sensor where pipe is used as a wave guide.

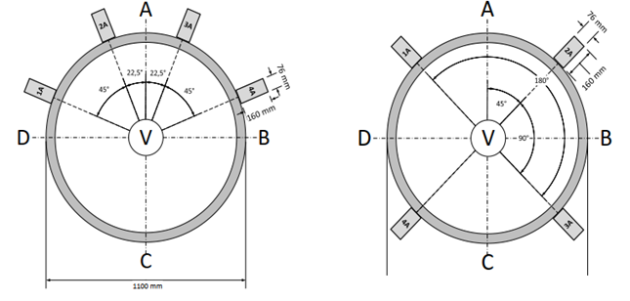

For improved flow profile average in demanding applications, clamp-on flow sensors can be installed with 1, 2, 3 and 4 path on a single pipe in reflect mode or in direct mode shown below in figure 3.

Figure 3: Four path installation in reflect mode (Left) and direct mode (right).

Higher performance with Digital SITRANS FS230

Instant digitalization of the signal, improved signal to noise ratio and reduced susceptibility to noise enhances SITRANS FS230 accuracy up to +/- 0.5% to +/-1% and repeatability of +/- 0.25% (ISO 11631). It brings the advantage of a wider turn down ratio, which means it can measure very low flow of liquids and very high flow of gases. The fast update rate of 100 Hz from sensor interface to the transmitter and control system enables FS230 to detect and update any minuscule flow changes within 10 mS.

The digital sensor link (DSL) is the crucial link between the sensors FSS200 and the transmitter FST030. The DSL electronics module receives the analogue signals from the sensors and digitizes them to send them on to the transmitter. A SITRANS FS230 flow system comes with two options: an integrated DSL for ordinary area installations, or the external variant in an explosion-proof housing for installation in Zone 1 hazardous area locations.

SITRANS FS230 with digital platform, accurately measures volumetric flow in standard applications, but also in complex applications it can accept pressure and temperature sensor inputs to provide accurate mass flow and volumetric flow at standard (or normal) conditions. I It makes a product identification of hydrocarbons liquids in oil pipelines using a relation between their speed of sound, temperature, viscosity, and density. The process values along with extensive diagnostics parameters are available on local HMI and communicated to control systems via HART or Modbus for the operator to verify whether the flow meter is accurate and healthy or there is any process issue.

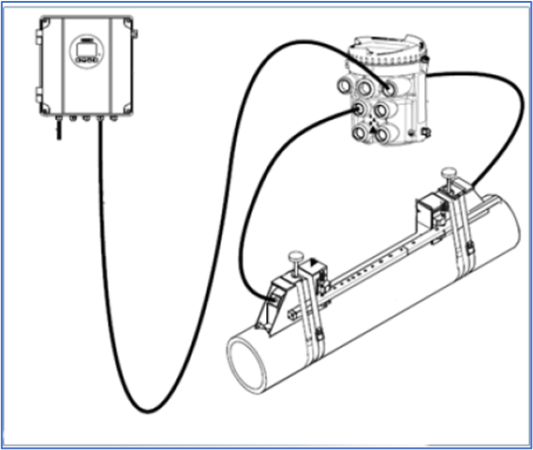

Figure 4: The Siemens SITRANS FS230 Flowmeter System combines SITRANS FSS200 sensors and SITRANS FST030 Transmitter.

APPLICATIONS:

SITRANS FS230 is ideal for measuring hydrocarbon liquid applications

The oil industry of Canada engaged in oil exploration, storage & transfer, refining and supplying the finished products to their customers are using Siemens clamp-on flow meters to measure flowrates, density, or interface measurement for identification of different products flowing in the pipeline.

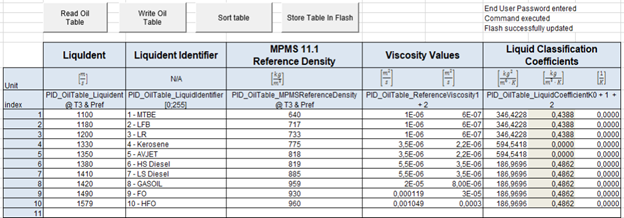

The challenges are the varying flow rates, considering different products in the pipeline, temperature changes, the associated change in viscosity and flow behavior. A temperature measurement, either directly via a sensor or as an external analog input signal, is necessary. Based on the actual measured values of the current speed of sound, the measuring device accesses an internal oil table considering the current temperature. Aided by the table, the transmitter identifies the measured liquid, determines the current density & viscosity, calculates the Reynolds number, and corrects the volume flow accordingly. The measuring device always shows the currently recognized liquid on the display but is also able to output the current mass or a standard volume calculation. Cleaning pigs briefly interrupt the ultrasonic measuring paths and are thus reliably recognized as a pig run.

Figure 5: Oil Table (former Liquident table) stores 32 common products Gasoil, Diesel, Kerosene etc.

Figure 6: SITRANS FS230 measuring hydrocarbon liquids with 4 path installation of wide-beam SITRANS FSS200 sensors in reflect mode, clamp-on temperature sensor in Zone 0, external DSL in Zone1 and wall mounted SITRANS FS230 about 100 meters away in Zone 2 hazardous area.

SITRANS FS230 in gas flow measurement applications

Typical applications are checking of the permanently installed flow meters, measuring high pressure gas networks, gas power plant compressors, gas inventory balancing, gas production in chemical industry and temporary billing. The pipe sizes it can cater are DN50 to DN1500 sizes with minimum pressure of 8 bars in steel pipes and velocity of gas up to 40 meters/sec.

The SITRANS FS230 flow system for gas measurement consists of two/four pairs of SITRANS FSS200 wide beam clamp-on sensors, internal or external digital sensor link and a SITRANS FST030 transmitter as in figure 10 below. Temperature changes via external sensor or analogue input and pressure changes via analogue inputs to FST030 are necessary for mass flow and standard volume flow corrections.

Figure 7: Clamp-on flow meter SITRANS FS230 system components and natural gas flow measurement application with “Soundcoat” to enable operations at low amplitude signals found in gas measurement.

Sending ultrasonic signals through a gas is a challenge. At low pressure conditions, the signals are being scattered a lot more, causing a lower signal-to-noise ratio. Using Lamb wave Sensors with Wide Beam Technology can remedy this. Flow speeds of up to 40 m/s and more can cause beam blowing but the angle of incidence is much smaller than in liquid applications and thus the sensor distance is also smaller which mitigates the effect of high flow speeds on the sonic signals.

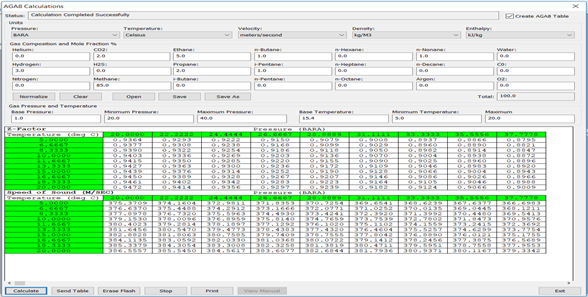

SITRANS FST030 transmitter has an internal AGA 8 gas table, which was created with the current gas chemical composition, taking pressure and temperature into account. Based on the actual measured values of the current flow rate, the FS230 accesses the AGA 8 gas table and determines the current viscosity, calculates the Reynolds number, and corrects the volume flow accordingly and able to output the current volume or to carry out the mass or a standard volume calculation.

Figure 8: AGA8 gas table to determine speed of sound in natural gas & hydrocarbon gases.

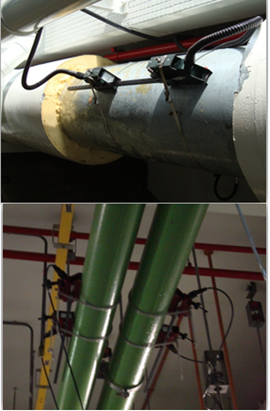

SITRANS FS230 applications in other industries SITRANS FS230 advancements have made the clamp-on flow technology more accurate, reliable and user friendly. Water and wastewater industry is the classic example as in figure 12 below where in the assets like piping network and pumping stations are quite old and needs to measure the discharge flow from the pumping stations or a leak detection in the piping network. Similarly, in the district energy industry that supplies hot and chilled water for heating and cooling applications. Here the customer wants to measure liquid flow, but also wants to measure the energy usage for billing to their customer. The SITRANS FS230 clamp-on flow meter is an ideal solution with its patented pipe configuration algorithm for Reynold number correction to minimize the error under non-ideal installation conditions with excellent signal to noise ratio and fast update rates measure the flow and flow total data with other important information can be logged and viewed. The Energy meter SITRANS FUE950 energy calculator along with two matched pair temperature sensors mounted in supply and return line calculates the energy flow with input of flow rate from SITRANS FS230.

Figure 9: Typical water & wastewater pumping station and hot & chilled water lines with installation constraints. Energy calculator & matched pair temperature sensors for energy measurement.

Local manufacturing and Digitalization

Siemens in Peterborough is a local Canadian manufacturing hub of Siemens process instruments including Clamp-on flow meters and delivers quality instruments with the shortest lead time possible.

Also, the clamp-on flow meter SITRANS FS230 are easily integrated into the cloud-based Siemens Mindsphere Platform for leak detection and similar remote applications using Siemens Apps.

Siemens Process Instrumentation products are distributed in Quebec and Ontario exclusively by Franklin Empire.

Links for more information: 1) www.siemens.com/fs230 for technical information case studies and PIA life cycle portal

2) https://buntplanet.com/tag/ai/ Siemens SIWA Leak plus

3) https://www.youtube.com/c/Siemens/search?query=fs230 Siemens FS230 videos

4) https://franklinempire.com/en/flow-measurement to book a meeting with a Franklin Empire Process Instrumentation Specialist

About the author: Vijay Acharya M.ENG, P.ENG is the Sr. Product Manager (Flow Products), Siemens Process Instruments, Oakville Ont. He has more than 30 years experience in Process Measurement and Control applications support, product management and product marketing.

Print this page