Tech Notes: Why peristaltic pumps excel in wastewater handling

By Sebastien Brosse, Team Leader, Abaque

Features Abaque Dover hose peristaltic pumps PSG wastewater handling

For more than two decades, peristaltic (hose) pump technology has proven to offer the performance and reliability that can make it a first-choice pumping option for wastewater treaters who crave highly reliable, environmentally friendly, low-maintenance pump operation.

No life form, whether it be human, animal or plant, can survive without water. That makes the reliable supply of clean water to homes, businesses, hospitals, and industrial-manufacturing facilities, among many others, of paramount importance. It also elevates the importance of a properly functioning municipal water-treatment facility.

Abaque’s peristaltic pumps feature a seal-free design and robust construction, allowing them to eliminate leaks and contamination and reduce maintenance and repairs.

These facilities have a twofold purpose: provide clean water to the masses and treat the fouled wastewater that they receive in return. Pumps play a significant role in wastewater-treatment operations, and over the years, many different styles and types have been used to handle impure, particulate-laden water, along with the various abrasive, corrosive and toxic chemicals that are used to clean it.

There is one type of pump technology — the peristaltic pump — that often outshines the others, especially when addressing the plant operator’s concerns regarding whether the pump is robust enough to handle the demands of a wastewater-treatment operation.

The twofold nature of wastewater-treatment facilities – treating fouled wastewater and providing clean water – require pumps that can handle a variety of fluids.

The key to the success of the Abaque pumps in handling these diverse fluid characteristics and operating conditions is the peristaltic pumping principle:

- High Performance: The pump’s seal-less design eliminates leaks and the possibility of product contamination, while providing the ability for continuous dry-run operation without adversely affecting the pump’s performance, pressure and dosing accuracy.

- Reliability: Peristaltic (hose) pump design requires none of the seats, valves and mechanical seals that can fail on other pump styles; the pump hose is its only replacement part.

- Versatility: The peristaltic pump can successfully handle extremely abrasive and aggressive fluids, solid-laden slurries, and water-thin, shear-sensitive, and viscous materials.

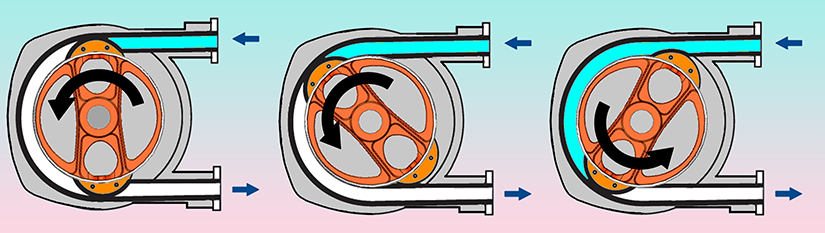

Peristaltic pumps use a hose and an internal revolving mechanism (rollers or shoes). The fluid flows through the hose, with the revolving shoes compressing it to push the fluid forward. When the shoes finish their rotation, the hose returns to its original shape and the process starts over.

Making The Case

Peristaltic pumps stand out because their operation is based on the alternating contraction and relaxation of the hose, which forces the contents to move through the pump and into the discharge piping. The smooth-wall, flexible hose is squeezed between shoes on the rotor and the inside of the pump casing.

This rotation moves the product through the hose at a constant displacement rate. The hose restitution after the squeeze produces an almost full vacuum that draws more product into the hose from the intake piping. The pumped product only contacts the hose and inserts, making this pumping technology very suitable for abrasive and corrosive applications.

Peristaltic pumps can transfer solids and soft particles, as well as handle water-like viscosities as high as 352,000 SSU (70,000 cSt), making them suitable for industrial wastewater and municipal water treatment facilities.

Peristaltic pumps also maintain excellent volumetric consistency, making them ideal for the strict dosing and 24/7 operating cycles that can be required in wastewater-treatment applications. Peristaltic pumps are also easy to operate and maintain, and their reversible operation allows for pumping in both directions, if needed.

To successfully handle the challenges of wastewater treatment, the pump’s hose and inserts need to offer the highest level of material compatibility, while also being able to reliably deliver the millions of pumping cycles that are required during their lifetimes.

The construction of a peristaltic pump is simple in scope, with its major components consisting of a rotor, pump case, gear motor, shoe and hose among others.

A critical consideration when selecting the hose material is its “fatigue resistance.” This trait defines how resistant to failure the hose material is as it runs through its millions of pumping cycles.

A hose material that is susceptible to developing cracks and holes early in its operational life is not as desirable as a material that can reliably handle the demands of the repeated contraction and relaxation of the hose, especially when particulate-laden liquids are being pumped.

The hose serves as the only wear part on a peristaltic pump, which has minimal components compared to other positive displacement pumps.

The reinforced construction of the peristaltic hose and its use of rubber compositions (natural rubber, EPDM, Buna-N, etc.) that have been specially designed for the stresses within the peristaltic hose allow for the optimum life cycle and performance.

For more than two decades, peristaltic (hose) pump technology – as epitomized by the standard-setting operation of the Abaque Peristaltic (Hose) Pump family — has proven to offer the performance and reliability that can make it a first-choice pumping option for wastewater treaters who crave highly reliable, environmentally friendly, low-maintenance pump operation.

Sebastien Brosse is Team Leader, Abaque and can be reached at sebastien.brosse@psgdover.com. Abaque is a product brand of PSG, a Dover company, Oakbrook Terrace, IL. Abaque products are distributed in Canada by Integral Process Equipment Inc. with offices in Montreal and Burlington, ON.

Print this page