H2O Innovation Inc. of Quebec City has announced that its Water Technologies & Services (WTS) business line was recently awarded four new contracts, including two industrial and two municipal projects. These new contracts amount to $13.6 million and increase the corporation’s WTS backlog to $76.7 million.

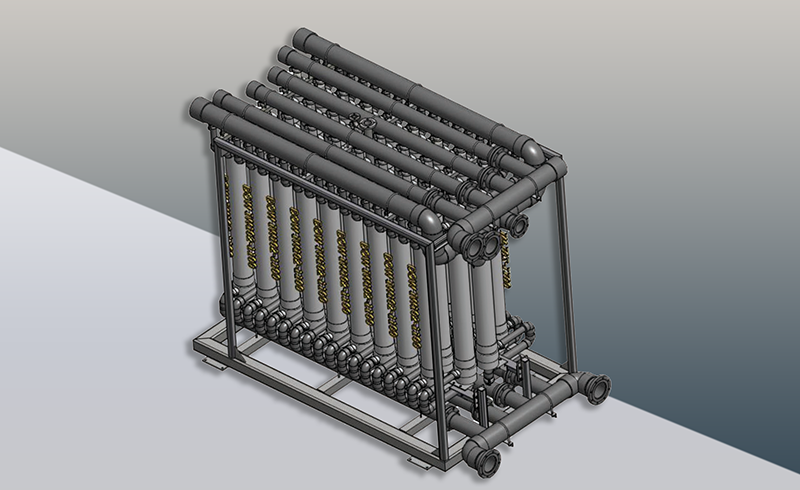

All four projects employ reverse osmosis (RO) with pretreatment using H2O Innovation’s FiberFlex ultrafiltration (UF) technology (pictured above), which provides clients with the flexibility to select the UF membrane type that is best suited for their water treatment needs and the option to replace it later with a different type of membrane. The core of the technology is a versatile skid design that accommodates a wide range of module types.

The corporation’s two new industrial projects are for clients located in Kentucky and in Bécancour, QC. The first industrial project centres on water reuse and involves the treatment of industrial wastewater using UF and double-pass RO processes for reuse as deionized water for a confidential client.

Under the second industrial contract, which H2O Innovation has secured with a manufacturer of components for lithium batteries, the corporation will provide a system that will be used to treat water from the St. Lawrence River to supply ultrapure water for industrial processes.

This comprehensive treatment system includes UF for pretreatment, followed by a double-pass RO system and electrodeionization (EDI) to obtain high-quality water. This project also highlights the importance of having strategically located installations, as the proximity of H2O Innovation’s Ham-Nord facility to the client was a contributing differentiator that helped the Corporation secure this contract.

H2O Innovation has also been awarded two municipal projects, both of which are dedicated to the treatment of river water to ensure safe drinking water for the Fox Lake and Garden River communities within the Little Red River Cree Nation in Northern Alberta.

The Fox Lake and Garden River systems are engineered to handle capacities of 1.2 MGD and 0.6 MGD respectively. These treatment systems employ high-pressure membranes to effectively separate total organic carbon, thereby ensuring the removal of disinfection by-product precursors from the water sources, the company says.

Print this page