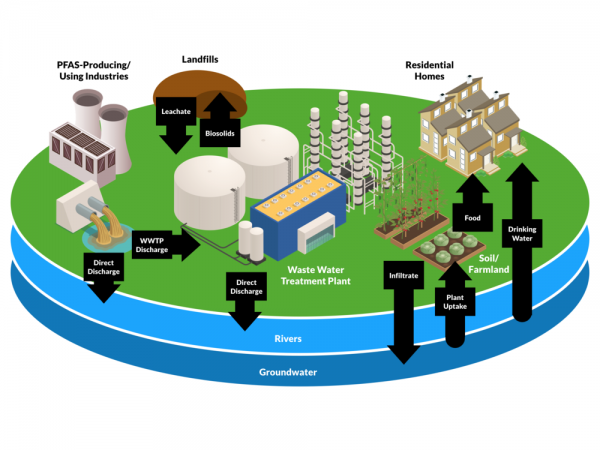

Enterprises that use water in manufacturing processes – or simply pass water through their facilities – have a new legal threat: Per- and Polyfluorinated Alkyl Substances, a class of more than 4,000 man-made chemicals known collectively as PFAS.

These chemicals have been added to consumer and industrial products since the 1940s, ranging from the production of nonstick cookware and food packaging, to stain-resistant fabrics and firefighting foam.

Recent studies indicate that PFAS exposure in humans can affect the immune system, increase the risk of prostate, kidney, and testicular cancers, as well as affect birth weight, growth, learning, and behaviour of infants and older children, lower a woman’s chance of getting pregnant, and disrupt the body’s thyroid hormones. Unfortunately, PFAS chemicals are extremely persistent so they will ‘bioaccumulate’ in human tissue over many years.

For example, the U.S. Centers for Disease Control and Prevention reports that PFOA, the toxic PFAS chemical used to make Teflon, is now in the blood of 99 per cent of Americans.

To limit legal exposure for manufacturers using water in their operations, Hacha Products Corporation has launched SolvePFAS, a vertically integrated laboratory solely dedicated to PFAS risk assessment and mitigation solutions. By integrating environmental science, thought leadership, advanced laboratory research, and data analytics, SolvePFAS gives manufacturers highly defensible data concerning their own environmental impact and potential role in human health endangerment.

“PFAS is now in the spotlight of environmental, health and safety watchdogs who are uncovering the catastrophic effects already here or lurking in the shadows,” said Kimberly Meek, owner and CEO of Hacha Products. “Who is in the legal crosshairs? Industry, to be sure. Risk management for exposing consumers to PFAS is fast becoming a lead-off topic in C-suite and boardroom discussions, which is where SolvePFAS data and analysis can play a major role in limiting vulnerability to costly lawsuits. PFAS risk exposure is almost certain to eclipse asbestos risk for companies, large and small, with no end in sight.”

SolvePFAS collaborates with world class research institutions, including The University of Chicago’s Pritzker School of Molecular Engineering, The UChicago Center for Data and Computing, Argonne National Laboratory, Searle Chemistry Laboratory, The University of Illinois at Chicago Mass Spectrometry Core, and best in class industry leaders like Agilent Technologies to help manufacturers determine PFAS toxicity in its influent and effluent water.

SolvePFAS collaborates with world class research institutions, including The University of Chicago’s Pritzker School of Molecular Engineering, The UChicago Center for Data and Computing, Argonne National Laboratory, Searle Chemistry Laboratory, The University of Illinois at Chicago Mass Spectrometry Core, and best in class industry leaders like Agilent Technologies to help manufacturers determine PFAS toxicity in its influent and effluent water.

It has a dedicated private laboratory in Chicago, Ill., where it prepares, tests, and analyzes samples its field technicians collect, ensuring the entire process stays in full compliance with US EPA Method 537.1. Meticulous control enables SolvePFAS to accurately capture trace levels of PFAS in the parts per trillion range, and vertical integration provides for a short chain of custody and dramatic reduction in testing turnaround time from weeks to days.

PFAS Risk Management Through Data

Every company that uses water in its manufacturing processes – or simply passes water through its facilities – has a new risk profile.

Consider, for instance, an industrial parts plater that purchases water from the local municipality. The influent water comes in the front door, is used in the plating process, cleaned up, and effluent is dumped down the drain. Operations are compliant with the permits, making it a closed loop between the municipal Publicly Owned Treatment Works (POTW) and industry.

Fast forward to the POTW testing its water and finding PFAS at 10 ppt (parts per trillion) with pressure mounting to find the source. The POTW looks upstream to the discharge permit holders and takes tests at the drains. The plater’s effluent measures at 10 ppt, making them the presumed responsible party and the legal system rumbles to life.

However, what if the plater had defensible data substantiating their plant was not the PFAS source? What if exculpatory data revealed that the water was already at 10 ppt when it came in the front door? Owners, CEOs, Board Directors, and legal teams armed with data can effectively hedge emerging PFAS risk.

www.solvepfas.com

Print this page