A new alliance called COMEDCO has been formed to assist pharmaceutical companies with their start into the manufacturing and packaging process of transdermal dressings and oral dispersible films. The technology firms Coatema Coating Machinery and Optima life science are behind COMEDCO with their combined expertise in converting and coating with pharmaceutical medicines.

Today’s technology offers new methods to administer medication, the alliance says. Pills and syringes will remain; however, there are many reasons to expand how to administer medications. An example is older people in need of care who have difficulty swallowing and where pills might not safely reach the intended “target”. Or illnesses, which may require frequent shots. Cases like these require alternative solutions that are still effective but more convenient for the patient.

It also makes sense to transport the substances as close as possible directly to the affected area during administering, the alliance says. A lower drug concentration and less stress to the gastrointestinal tract are additional advantages to choose transdermal dressings or oral dispersible films.

A higher demand in oral dispersible film (ODF) and transdermal dressings (TDS – transdermal systems) is already apparent for the machine manufacturing industry.

The idea behind COMEDCO is to make it easy and safe for pharmaceutical companies to start their new developments for transdermal and ODF products. The COMEDCO portfolio includes laboratory or development equipment platforms, which are scalable to medium and large size production capacities.

Development expenses occur during the launch of ODF or TDS product. Here the machine builder can help to reach the objective faster and with less expenditure. Answers to questions like: What is the best suitable application and dosing system for a certain drug? What is the best carrier material for which drug? How can a correct homogeneous substance per piece or unit be guaranteed and controlled?

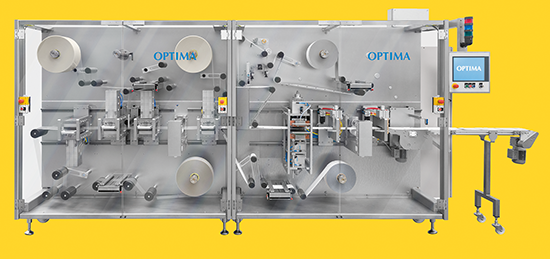

The production of transdermal dressings and ODF products starts with the coating process where the substance is applied to the carrier material by a COMEDCO machine. Depending on the product, a certain drying time has to be considered which takes place within the machine.

Subsequently the carrier material with the applied substance is cut and rolled into individual rolls. The product, depending on the drying process and the strict separation of different pharmaceutical substances, to avoid cross-contamination, may require a batch process. The coating process takes place in the first part of the COMEDCO machine.

The packaging process is completed in the second part of the COMEDCO machine. In this part of the machine, existing (product depending) carrier material can be removed, new carrier material introduced, film would be cut to a defined size, separated and reunited on a carrier film and packaged. Packaging of transdermal dressing is often more complex than packaging of oral dispersible film due to a wider variety of product options and different processing methods. The COMEDCO machine offers continuous or intermittent converting and packaging processes.

Print this page