Tapmaster launches stainless-steel metal 3D printing division ready to support oil & gas

Mike Edwards

News People in Process 316L stainless steel 3D printer binder jet style oil and gas parts SumMetal Printing Tapmaster

Tapmaster Inc. has recently launched a new division under SumMetal Printing in Calgary to provide rapid prototyping and short-run production to local businesses and entrepreneurs, including those that support the oil and gas industry.

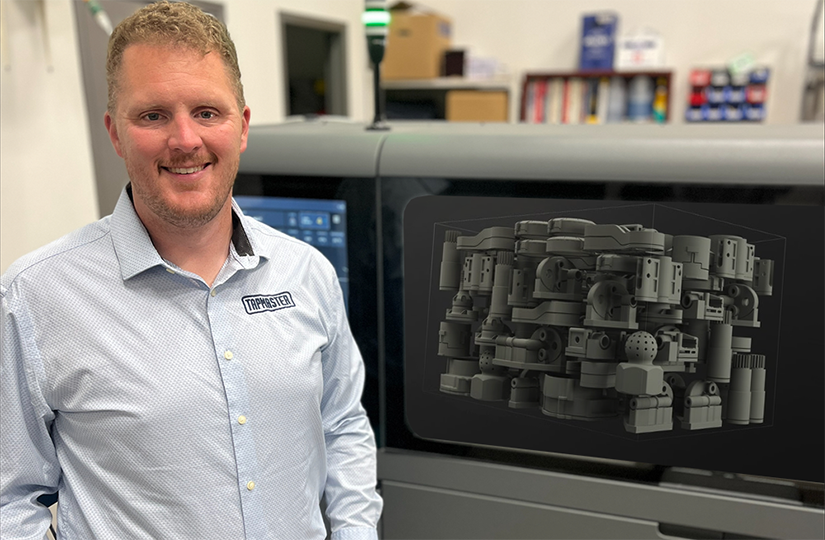

Tapmaster is said to own the only Desktop Metal Shop System printing in 316L stainless steel for direct contract use in Canada. According to Tyler Pubben (above with nested 3D parts inset illustration), president and VP Development of Tapmaster Inc./SumMetal Printing, the system can create parts such as nozzles, valves, and fittings, for field applications either for emergencies or planned short production runs.

“Parts created offer corrosive resistance to drilling mud and other caustic down hole fluids,” says Pubben. “The system can also build complex fluid nozzles that would be too expensive to machine using traditional metalworking methods.”

Pubben notes that the company acquired the technology to produce valves for its established Tapmaster plumbing valve manufacturing business and created the division to exploit its throughput capabilities.

The system is a binder jet style 3D printer. This technology is said to allow for hundreds of different parts to be printed simultaneously with a much finer surface finish than DMLS (direct metal laser sintering) technology.

This allows for loads with multiple different parts, or short run production of final end-use parts, the company says. When complete, the parts produced are 99 percent dense and contain no impurities making them suitable for use in any environment where MIM (Metal Injection Moulding) or casting would be used, it adds.

The high resolution of the printer is said to also allow for parts to be made that would otherwise need to be machined. Fine pitch threads and small orifices are all able to be printed without post-processing in many cases.

Compared to traditional manufacturing methods, binder jet printing is said to have several key advantages:

- No tooling costs

- No setup time

- Little to no post-processing

- 96-hour turnaround times are possible

“We are very excited to bring this new manufacturing technology to market in Canada. We hope to help accelerate the already impressive growth in the local manufacturing and start-up community,” adds Pubben.

Print this page