Application Note: Chlorine dioxide generator uses normally-closed solenoid valves

Mike Edwards

Features chemical sight glass chlorine dioxide generation Plast-O-Matic Valves solenoid valve thermoplastic ChO2 generation schematic: The chemistries and the reaction agent are drawn through the valves via vacuum.

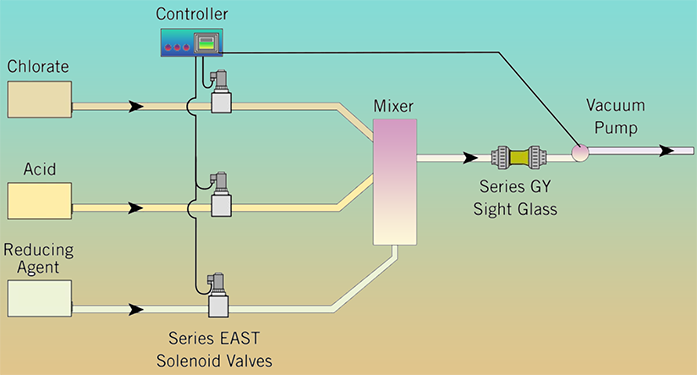

ChO2 generation schematic: The chemistries and the reaction agent are drawn through the valves via vacuum. Chlorine dioxide generation usually relies on consumable hardware items, such as catalysts or resin cartridges. By using thermoplastic solenoid valves to control chlorate, acid, and the reducing agent, the need for cartridges or other consumables is eliminated.

The chemistries and the reaction agent are drawn through the valves via vacuum.

When the pump runs, the controller energizes the solenoid coils to open the valves. A 1/16 in. orifice limits flow, while the energized coil holds the valve shaft open despite the vacuum condition.

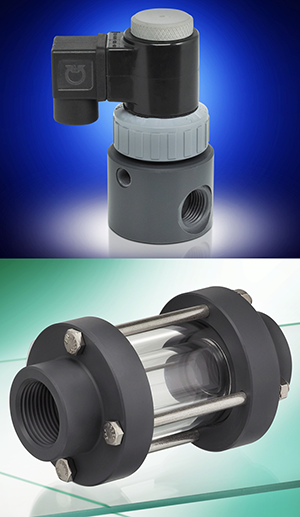

When the pump shuts off, the coil is de-energized, and a spring automatically returns the valve to the closed position. The metal spring and core are isolated from the process by a PTFE bellows design, which also prevents fugitive emissions.

Unlike typical resin cartridge systems, the valves require no regular maintenance and are rated to 2,000,000 cycles. At that point each valve can be rebuilt with a seal kit.

Reaction occurs in a mixer, and the process can be visually verified from time to time via thermoplastic sight glass, which also has no wetted metals.

For more information and solenoid valve specifications from Plast-O-Matic, please click here. For information on chemical sight glasses, please click here.

Print this page