Food Purity: Berryhill Foods finds sweet success with metal detectors

Mike Edwards

Features Eriez Xtreme Eriez Xtreme metal detector models used at Berryhill are offered in 6-, 12- and 18-inch belt sizes. The units offer options such as push arm or air blast rejects, lockbox, reject confirmation, emergency stop and side guides.

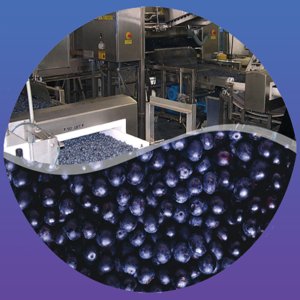

Eriez Xtreme metal detector models used at Berryhill are offered in 6-, 12- and 18-inch belt sizes. The units offer options such as push arm or air blast rejects, lockbox, reject confirmation, emergency stop and side guides. Founded in 1994 in the heart of the Fraser Valley in British Columbia, Canada, Berryhill Foods specializes in the processing, freezing, marketing and distribution of cultivated blueberries and red raspberries. Long-standing customers use berries from the company’s annual crop harvest of 22 million pounds for their popular lines of jams and jellies.

While Berryhill’s customers vary, their exacting standards do not. These customers demand stringent adherence to safe quality assurance measures, particularly when it comes to detecting and eliminating metal particles in the raw berries prior to shipment. To meet Hazard Analysis and Critical Control Points (HACCP), Safe Quality Food (SQF) and other food safety guidelines, Berryhill relies on nine Eriez metal detectors in its various plant operations. Management says plans are underway for installation of additional Eriez metal detectors.

“The Eriez metal detectors are required on all of our lines because they are considered critical control points by our food safety systems, including SQF and HAACP,” says Berryhill Foods maintenance manager Tom McTaggart. He explains, “Our pre-pack processing lines have two metal detectors each because we want to have one detector as the last step before the boxes are stacked for storage.”

While there are many factors that contribute to the volume of berries going through the metal detectors, McTaggart says the average is 10,000 pounds per hour during the harvesting season.

http://berryhillfoods.com/ Berryhill Foods has been an Eriez customer for more than two decades. “We have been using Eriez metal detectors since the mid-90s,” explains McTaggart. “In an effort to achieve an even higher level of sensitivity,” he adds, “we are in the process of converting several of our long-standing units into the newer Eriez Xtreme models.”

Watch demonstration of Eriez Extreme metal detector:

Eriez says the Xtreme models which will be used at Berryhill are offered in 6, 12 and 18-inch belt sizes. These state-of-the-art units offer new options, including push arm or air blast rejects, lockbox, reject confirmation, stainless steel motor/reducer, improved guarding, emergency stop and side guides.

According to the company, the Eriez Xtreme metal detector interface is icon-driven and patterned after advanced smartphones. Plant operators receive instantaneous visual feedback from the screen in real-time to make decisions regarding the equipment’s set-up and performance.

Meeting customers’ product purity specs

This ability to monitor and report on the precise level of metal detection in the harvested fruit crop is vital to Berryhill’s customers, which are in the United States, Europe, Asia and throughout Canada and each have their own specific set of food safety criteria. Regardless of the customer or their location, Berryhill says it strives to meet the same standards for quality, integrity, and excellence.

McTaggart explains, “We have customers who send us test pieces– like 3 mm stainless steel or 2.5 mm nonferrous, for example–to determine how well the metal detectors are performing before they receive shipment. Every year, I receive a detailed report from Eriez verifying that their metal detectors are meeting our sensivitiy requirements and I pass that along to our customers.”

The main bulk of product is sent through three Individually Quick Frozen (IQF) lines that run 9,000 to 15,000 pounds an hour and freeze the berries in six to 20 minutes.

McTaggart says this is important because some of Berryhill’s customers produce fruit blends containing four to five different types of fruit from various suppliers. “Sometimes,” he explains, “they will discover contamination in that blend and look for which provider sent the contaminated fruit. We can tell the customer that our Eriez metal detector can monitor a fragment up to 1.5 millimeters, so there is no way that the metal detector would miss the 3-millimeter lead shot sample size they sent.”

McTaggart continues, “We then tell the customer that our Eriez metal detectors will always detect the size of test metal sample they send, so they will continue to look for another supplier to determine where that stray metal is originating.”

The Eriez metal detectors in use at Berryhill Farms combine a precision mechanical design with state-of-the-art electronics, multiple frequency range, vibration immunity and complex algorithms to detect the smallest metals in food products. The upgraded Xtreme units have the ability to find smaller metal contaminants than previous metal detectors, even in difficult applications like harvested berries.

Producing a rich berry harvest

Premium berries from Berryhill Foods are grown on the company’s own family farms and by carefully chosen independent regional growers, which are third-party certified for good agricultural practices (GAP). The rich, fertile soil conditions and temperate climate of southern British Columbia produces more cultivated blueberries and red raspberries than any other region in Canada.

The company has three separate locations throughout the region, two of which have cold storage while the third is a single processing line. Its newest facility, which opened in 2017 in the heart of Chilliwack’s British Columbia’s Agricultural Food Processing zone, contains 50,000 square feet of cold storage space.

Berryhill has three different locations for its blueberry and raspberry production throughout southern B.C., two of which have cold storage while a third is a single processing line.

“The main bulk of product is sent through three Individually Quick Frozen (IQF) lines that run 9,000-15,000 pounds an hour and freeze the berries in six to 20 minutes,” McTaggart says. “We have other processing lines that will ‘puree’ raspberries or run them up an inspection belt to be packed into large drums then shipped out to be turned into jam.”

McTaggart explains that once the berries are processed and conveyed through the Eriez metal detectors, they are packed into either 30-pound boxes, 28-pound pails 55-gallon drums or 1,500-pound totes. “Not only do we sell to our long-time major customers, but we also sell to companies that will put our fruit into either a poly bag fruit blend or a poly bag of just blueberries. Others use our fruit for pie fillings,” he notes.

As an industry leader, Berryhill Foods continues to invest in the most up-to-date equipment and staff training programs, according to McTaggart. The company’s strict SQF certified food safety system and its advanced processing equipment—coupled with the integration of the various Eriez metal detectors—allows Berryhill Foods to offer customers a ready-to-use premium product of consistent high quality.

“We strive to keep all our growing, cultivation and processing the same so we can sell to numerous customers around the world,” McTaggart explains. “Our goal is to consistently earn a high grade on the SQF audits because that’s what our customers look for and it gives us a higher standing with them. The Eriez metal detectors we have throughout our facilities are critical to helping us meet those stringent guidelines.”

This article was contributed by Eriez, a manufacturer of magnetic lift and separation, metal detection, fluid recycling, flotation, materials feeding, screening, conveying, and controlling equipment. The equipment has applications in the process, metalworking, packaging, plastics, rubber, recycling, food, mining, aggregate and textile industries.

Print this page