Closed-loop control advances lab automation with high-throughput pipetting

Mike Edwards

Products DHOP pipette EXCL multi-axis gantry festo fluid handling lab automation

Festo has introduced the DHOP closed-loop pipette head for high-speed robotic pipetting applications delivers consistent volumes over a wide range of liquid viscosities.

Based on the company’s air-over-liquid fluid handling system, the DHOP pipette is said to ensure that aspiration and dispensing are independent of viscosity.

Liquid aspirates into the disposable tip using vacuum and dispenses using pressure to increase microfluidic speed and flexibility.

Watch video demonstration:

By measuring the pressure change when a liquid is aspirated or dispensed, the device is able to calibrate for different viscosities without user input. Faster changeover between liquids leads to higher throughput and maximum device utilization, the company says.

Applications for this closed-loop pipette head (above, right) include pre-analytical preparation of patient samples, where liquid properties might change from patient to patient.

The product is also said to provide the control system with feedback on every pipetted volume for traceability and quality assurance. The internal controller adjusts the target volume and returns the achieved value to the controller.

Pressure-based liquid level detection prior to aspiration ensures maximum precision and any foam on the surface is ignored in level detection, the company adds. The liquid velocity is adjusted by changing the pressure on the system; this allows for soft dispensing with sensitive media or better droplet separation with small volumes.

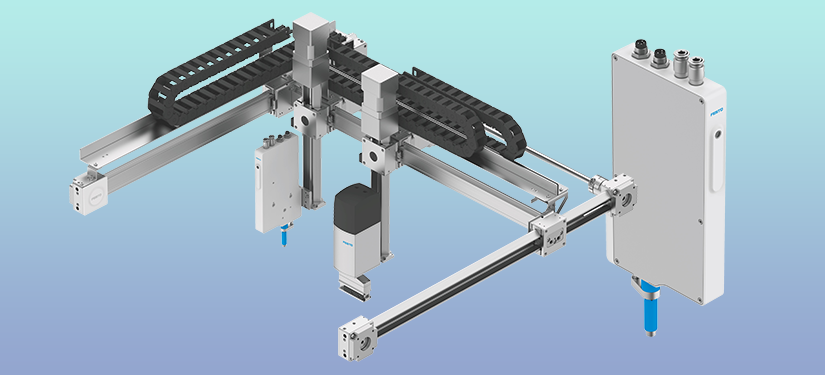

The pipette system integrates with Festo’s mechatronic systems, including the new EXCL multi-axis gantry (above left), to lower engineering, acquisition, and assembly costs while increasing machine capabilities.

Print this page