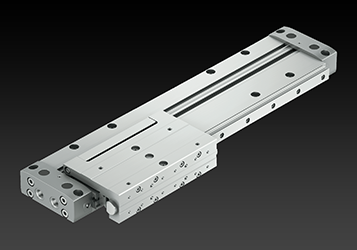

Festo has introduced the space-saving, flat, DLGF rodless linear drive, said to be an economical choice for applications where installation space is especially tight, like packaging and handling technology.

Since those space considerations can also make a pneumatic drive harder to adjust or service, Festo also says it made its proprietary self-adjusting end-cushioning (PPS) standard with DLGF. Self-adjusting cushioning saves time and makes processes more reliable; the drive is always providing the correct cushioning. (Poorly or incorrectly adjusted cushioning can lead to premature wear of a pneumatic drive or even product quality issues.)

With the guided version – KF– there are two different slide interfaces: one on the top for mounting pneumatic slides, and one on the side for mounting up to three ADN pneumatic compact cylinders. Two DLGF drives of the same size can be easily coupled together, although they can have different stroke lengths.

Print this page