Brought to you by ABB Measurement and Analytics

Streamlining Wet Well Level Measurement with ABB’s LLT100 Laser Level Transmitter

May 3, 2024 in Features

By Josee Labrecque, ABB Level Europe, Canada and Latin America Area Market

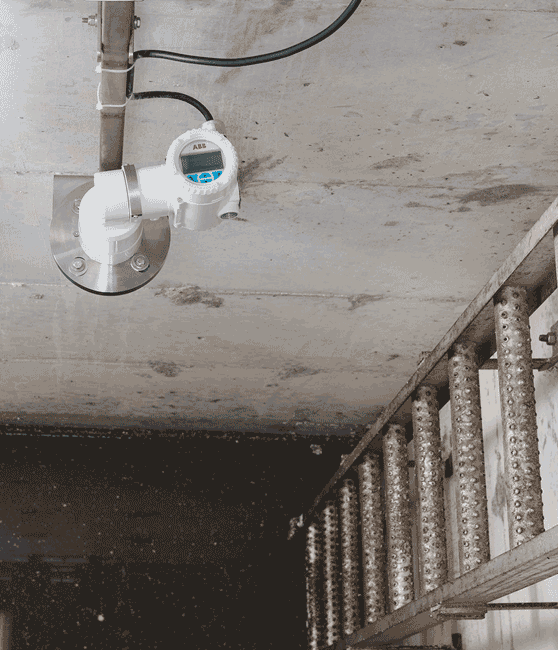

LLT100 installed in a water treatment plant (Photo: Courtesy of ABB)

LLT100 installed in a water treatment plant (Photo: Courtesy of ABB) In the water and wastewater industry, managing wet well level applications can be both labor-intensive and costly. Maintenance visits to numerous wet wells across expansive areas often result in significant expenditures on labor, travel, and related expenses like equipment cleaning and safety protocols.

Challenges Faced

Wet wells require frequent access for the maintenance of level measurement devices, often on a monthly or even weekly basis. This necessitates the presence of a two-person team and incurs substantial travel costs and on-site traffic management expenses. Moreover, unique process conditions within certain wells pose challenges for reliable level measurement, particularly in the bottom ±15% of the well.

Introducing a Simple and Accurate Solution

ABB’s LLT100 laser level transmitter presents a game-changing technology for level applications. This device operates on a line-of-sight principle, accurately measuring what it sees. The sensor unit is robust and requires minimal maintenance, reducing downtime and operational costs.

The autonomous measurement capability of the LLT100 eliminates several health and safety concerns associated with traditional methods, such as working at heights or in confined spaces. Furthermore, it does not necessitate on-site calibration, enhancing operational efficiency.

The LLT100 features a narrow laser beam that remains unaffected by structures, making it ideal for crowded wet wells. It can also measure mixing tank levels without interference from mixing blades, thanks to customizable dust application programs that adapt to varying environmental conditions, including fog and dust density.

Environmental Impact and Cost Savings

Continuous level measurement with the LLT100 significantly reduces the risk of overflow events, thereby minimizing potential environmental impacts and regulatory liabilities.

In conclusion, the line-of-sight measurement technology, rugged design, narrow laser beam, and low maintenance requirements of ABB’s LLT100 laser level transmitter address the key concerns associated with wet well level measurements. The potential return on investment is substantial, with savings on overtime alone often justifying the initial purchase.