Non-contact IR thermometers excel in paper temperature application

Mike Edwards

Features food IR sensors KPM Analytics pulp and paper temperature sensing

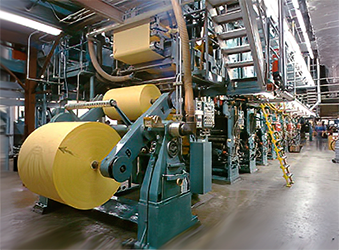

Sheet break prevention is a serious concern of pulp and paper manufacturers because breaks contribute significantly to increased production downtime and higher than normal operating expenses. Sheet breaks occur at several stages of paper processing but always cause troublesome delays.

Some of the reasons for sheet breaks accumulate gradually over time while other causes may occur suddenly and without warning. Paper manufacturers strive to get out in front of the problems and avoid downtime and cost overruns.

Process Sensors, the IR division of KPM Analytics based in Franklin Lakes, NJ, has recently stepped up and emerged as a problem solver for Advanced Technology Services, operating as the maintenance staff for United States Gypsum in North Kansas City, MO.

Toward that goal, Advanced Technology Services was looking to upgrade the United States Gypsum sheet temperature transmitter operation by replacing legacy Mikron Infrared model M67K (equipped with air purges) devices used for paper temperature measurement with much more up to date sensors.

Application specialists from Process Sensors were able to specify, quote and deliver several PSC-T42L model sensors that modernized the operation and fit the application perfectly.

The PSC-T42L devices are self-contained pyrometers intended for industrial applications and are 2-wire loop powered with a linear 4-20 mA output, making them very simple to install, the company says.

Operating in the -40° to 1000°C range, the T42L series provides on-board emissivity adjustment, high resolution, fixed focus optics and a selection of wavelengths. Temperature ranges can be factory set to a sub temperature range within the selected sensor’s overall temperature range span.

Users have a choice of integrated or optional battery-operated laser aiming lights. The PSC-T42L pyrometers have rugged stainless-steel housings and protective cooling/air purge assemblies for harsh industrial applications.

In addition, a wide range of electrical, mechanical, and optical accessories are available from Process Sensors.

Typical applications for model PSC-T42L pyrometers are paper and packaging, plastics, non-metals and coated metals, building materials and the food industry.

This article was contributed by Process Sensors.

Print this page

Advertisement

- Curtiss-Wright contract awards valued in excess of US$220 million

- Connection platform for pressure hoses

Non-contact IR thermometers excel in paper temperature application

Don Horne

Products Calibration Equipment Controls Instrumentation ippt TemperatureProcess Sensors, the IR division of KPM Analytics, has recently stepped up and emerged as a problem solver for Advanced Technology Services, operating as the maintenance staff for United States Gypsum in North Kansas City, Mo.

Sheet break prevention is a serious concern of pulp and paper manufacturers because breaks contribute significantly to increased production downtime and higher than normal operating expenses. Sheet breaks occur at several stages of paper processing but always cause troublesome delays. Some of the reasons for sheet breaks accumulate gradually over time while other causes may occur suddenly and without warning. Paper manufacturers strive to get out in front of the problems and avoid downtime and cost overruns.

Toward that goal, Advanced Technology Services was looking to upgrade the United States Gypsum sheet temperature transmitter operation by replacing legacy Mikron Infrared model M67K’s (equipped with air purges) used for paper temperature measurement with much more up to date sensors. The Application Specialists at the Process Sensors IR New Jersey office were able to specify, quote and deliver several PSC-T42L model sensors that modernized the operation and fit the application perfectly.

The Process Sensors’ PSC-T42L’s are self-contained pyrometers intended for industrial applications and are 2-wire loop powered with a linear 4-20mA output making them very simple to install.

Operating in the -40°C to 1000C temperature range, the T42L series boasts on-board emissivity adjustment, high resolution, fixed focus optics and a selection of wavelengths. Temperature ranges can be factory set to a sub temperature range within the selected sensor’s overall temperature range span.

Users have a choice of integrated or optional battery-operated laser aiming lights. The PSC-T42L pyrometers have rugged stainless-steel housings and protective cooling/air purge assemblies for harsh industrial applications. A full complement of electrical, mechanical, and optical accessories is available.

Typical applications for model PSC-T42L pyrometers are paper and packaging, plastics, non-metals and coated metals, building materials and the food industry.

www.processsensors.com

Print this page