Extended boiler life cycles depend on monitoring and maintenance

Mike Edwards

Features corrosion maintenance monitoring Yokogawa

Whether a boiler should be repaired or replaced is largely dependent on age and condition. Proper monitoring of water quality (pH, Cond, DO), chemical addition control (ORP), and real time corrosion control (ECP). Regular maintenance is important to prolonging the life of a boiler. However continuous of monitoring of water quality allows for predictive maintenance and prevention of shutdown.

For the pure water applications, the primary measurement encountered is conductivity.

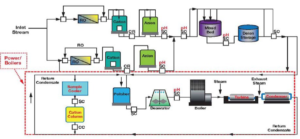

To defray energy costs, many industrial plants have their own boilers to generate steam to produce a portion of their energy needs. In addition, the steam may also be used directly in plant processes or indirectly via heat exchangers or steam jacketed vessels.

The problem for this application is that the raw water used to feed the boilers, contains varying levels of impurities that must be removed to protect the boiler and associated equipment.

Pretreatment processes such as reverse osmosis, ion exchange, filtration, softening and demineralization may be used to reduce the level of impurities, but even the best pretreatment processes will not remove them all and there will be a continuous carryover of some dissolved mineral impurities into the boiler.

Boiler feed water usually contains one limiting component such as chloride, sulfate, carbonate, or silica. Even if the component is not conductive, for example silica, its concentration is usually proportional to a component that can be measured by conductivity; therefore, conductivity is a viable measurement for monitoring the overall total dissolved solids present in the boiler. A rise in conductivity indicates a rise in the “contamination” of the boiler water. So, measuring conductivity of the feed water is important to this application.

The most common methodologies used for boiler blowdown control include: (1) continuous, (2) manual and (3) automatic.

Continuous blowdown — utilizes a calibrated valve and a blowdown tap near the boiler water surface. As the name implies, it continuously takes water from the top of the boiler at a predetermined rate to reduce the level of dissolved solids. The rate is usually set slightly greater than necessary to be on the safe side.

Manual blowdown — is accomplished at most plants by taking boiler water samples once a shift and adjusting the blowdown accordingly. This grab sample approach means that operators cannot immediately respond to changes in feed water conditions or variations in steam demand and scaling conditions can occur and go undetected until the next sample check.

Automatic blowdown control — is achieved by constantly monitoring the conductivity value of the boiler water and adjusting the blowdown rate and duration based on a specific conductivity set point. This provides control of the water chemistry regardless of the boiler load conditions. Actual operation data verifies that automatic control can maintain boiler water conductivity consistently within 5% of the set point. Manual blowdown control cannot maintain this level of control more than 20% of the time. Again, measuring conductivity is essential for controlling this application.

This article is excerpted from the Yokogawa Tech Note, Boiler Life Cycle Considerations. Click here to download the complete tech note.

Print this page