Pump up/pump down application requires smart ultrasonic sensor

Mike Edwards

Features liquid level monitoring turck

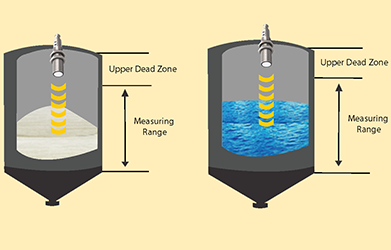

Monitoring liquid level in a tank or container is a very common application in industry. Water, glue, oil and other liquids need to be stored and pumped to and from various areas of a plant, process and area. Although on the initial look these applications seem quite easy they do require a level of control beyond a simple ultrasonic sensor.

A new programmable range of ultrasonic sensors can be set up to give optimal performance on applications requiring pump up/pump down control.

“Pump up” refers to the filling cycle of a vessel or container.

“Pump down” is the removal of liquid from the vessel or container.

The control is completed with the addition of a monitoring channel to alarm if the pumping activity causes the level to go above a high limit (causing an overflow condition) or below a low limit (causing a run dry condition).

Although not suitable for use in pressurized vessels, the Turck Ultrasonic type RU130U-M18E-2 UP8X2-H1151 (1610014) provides pump up function with alarm output, also called pump in function.

Print this page