Across process industries, the success of major capital projects is jeopardized by traditional automation system commissioning practices and their associated problems: missed deadlines, errors, and stretched-thin personnel.

Done right, commissioning can help teams meet schedule constraints and come in on budget. Choosing the right automation strategy can set you up for success.

Although automation expenditures are typically only three to four percent of the overall project, the automation system has a much larger impact on an overall project in areas such as process performance, adherence to schedule, and time to first product. See overview in video below:

Because automation is always on the critical path for start-up, and delays can cost millions of dollars per day, facilities constantly search for ways to be more efficient in commissioning. At times, the automation system itself puts up the roadblocks through difficult technologies and methods, which cause problems:

- Missed deadlines – Configuring intelligent field devices during commissioning demands a great deal of time from engineers, suppliers, and field technicians. Because everyone is stretched thin, both deadlines and opportunities are missed.

- Manual errors – With thousands of devices to configure, and dozens of parameters for each device, the potential for critical errors always exists. Managing the information required for device commissioning, finding available resources, and validating that configurations are correct pose significant challenges.

- Staffing demands – Traditional loop checking takes a coordinated testing effort from multiple people: technicians both in the field and in the control room. Step by step, the team goes through electrical and software loop validation. For each technician, the process holds a great deal of wasted, idle time.

Smart Commissioning

Smart Commissioning drastically reduces time and effort by providing an efficient progression from device installations to process startup. Laying the groundwork early in the process — before the binding of field devices — the method uses automation and field device data to streamline tasks all the way through loop testing and beyond.

Positively impacting the overall certainty of project execution, Smart Commissioning helps automation projects meet strict and shifting deadlines. New functionality in the DeltaV distributed control system (DCS) and AMS Device Manager asset management software improve device binding and configuration, testing, and documentation.

The basis of the process relies heavily on automating manual tasks and letting the technology do its work. Smart Commissioning improves traditional project execution methods into these efficient steps.

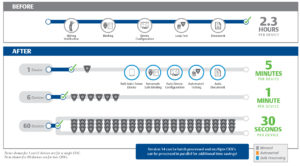

Automation and parallel processing enable commissioning to be completed in a fraction of the time per device.

Tag-Based Configuration — Configuration without waiting for I/O allocation

As soon as the initial I/O definition is available, the project team can start configuring control strategies based on the device signal tags (DSTs). Each I/O function block is linked to a DST that is not assigned to any particular I/O channel. In a traditional configuration approach, I/O references within the control strategies are bound to specific channels. This creates detrimental dependencies in the project schedule.

Smart Commissioning enables the team to delay binding I/O references until the field devices are wired at site — a process called late binding.

Connect Anywhere — Flexible I/O assignment independent of control design

The DeltaV Electronic Marshaling with CHARMs technology enables field cabling to be landed wherever it is required, regardless of signal type or control strategy. Each terminal block has a single channel CHARacterization Module (CHARM) that allows any field wiring signal type to be terminated in any location. Field wires are terminated on terminal strips, but the marshalling panel and the associated cross-wiring to I/O cards is no longer required. Each I/O channel is linked to its appropriate controller through the DeltaV system software. The ability for the DeltaV controllers to utilize I/O from different CHARM I/O cards (CIOC) simplifies design considerations for allocating devices to field enclosures.

Thanks to the broad range of I/O types, practically all field devices can be connected to the DeltaV CHARM I/O subsystem without requiring external components. A large variety of signal types, such as RTD, T/C, and 120VAC, can be used in the same field enclosure. The installer only needs to select the proper CHARM based on the signal type. All this field work can be done without any information about the logical I/O assignment within the control strategies.

Automatic I/O and Device Identification — Eliminate manual work

After the CHARMs have been installed in the system cabinet and each device wire has been terminated to a CHARM, each CHARM is automatically identified (or auto-sensed) by the DeltaV system. The user does not need to define the type for each I/O channel. HART devices are automatically identified when they are installed. The DeltaV DCS automatically retrieves device information such as manufacturer, model, revision, and tag. AMS Device Manager will then automatically configure the device based on a pre-defined template.

Automatic Binding — Error-proof entries

Smart Commissioning automatically binds field device references to control strategies via the field device tag. For HART devices, the binding of I/O references is performed automatically after the device has been discovered by the DeltaV system. If the device tag matches a DST within the system, the proper I/O function block is bound to the right field device automatically. Automatic binding enables late changes to be made simply without impacting the project schedule.

Automatic Device Configuration — Save time with bulk transfer

Smart Commissioning reduces time and errors associated with the traditional commissioning process. AMS Device Manager uses device templates and bulk transfer to efficiently configure field devices. Instead of configuring devices one at a time, bulk transfer enables configurations to be applied to devices simultaneously. Device templates ensure accuracy and consistency in the process. When templates are combined with bulk transfer, technicians can save hundreds of work hours.

Automatic validation reports in AMS Device Manager make it easy to quickly verify that devices are configured correctly. Discrepancies are clearly indicated and highlight the exact parameters that do not match. Validation reports can also help manage project changes, ensuring configuration updates have been applied correctly.

Automatic Loop Testing — Streamline testing with fewer resources

Once the device tag has been bound with the control strategies, the next step is to perform loop checks. Using DeltaV Device Commissioner a single technician at a control room workstation can execute loop checks without another technician working in the field. The system automatically documents all the steps, saving time in producing test reports.

Avoid Commissioning Overwork

Ask an Emerson expert to determine how much time and effort your team can save on commissioning and discover just how flexible your team can be as they easily adapt to late design changes. We look forward to implementing Smart Commissioning in your organization and ensuring more certain project success.

Up to 30 percent of anticipated value disappears during the turnover/commissioning and ramp-up phases of new asset lifecycles. – “Effective Operational Readiness of Large Mining Capital Projects” Deloitte, 2012.

This article is from a white paper by Emerson.

Print this page