Tribal knowledge: Industrial seal manufacturer cuts training time in half with work instruction software

Mike Edwards

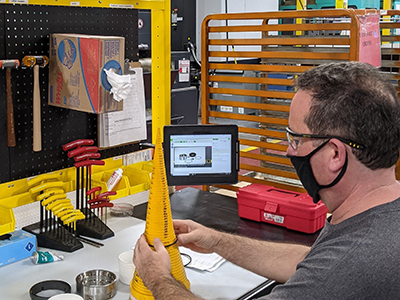

Features food & beverage seals training With multiple processes involving 60+ assembly steps, the job of a Chesterton operator is complex and requires a massive amount of competence. By incorporating our work instruction software into their operations, Chesterton has been able to share the experience and know-how of their employees with the next generation of workers.

With multiple processes involving 60+ assembly steps, the job of a Chesterton operator is complex and requires a massive amount of competence. By incorporating our work instruction software into their operations, Chesterton has been able to share the experience and know-how of their employees with the next generation of workers. Experienced workers are a major asset to any organization. They have the experience to solve complex problems and the vision to push forward under any circumstance. Training new employees to this level of proficiency takes countless hours… or does it?

Chesterton of Groveland, MA, is proving that with innovative tools like work instruction software from Montreal-based VKS, sharing advanced expertise and knowledge with the next generation of workers is easier and faster than ever.

Chesterton, with sales offices in B.C., Ontario, Quebec, and Nova Scotia, is a provider of sealing solutions that enable manufacturers to pump liquid and air reliably and efficiently. From a wide variety of mechanical seals to pump packing materials and more, Chesterton is a leader in design and quality.

With being the first company to offer commercially viable split seals for plant-wide use, Chesterton has a long-standing history of cutting-edge technology and innovation.

It was this drive towards innovation that led them to seek out the best methods to train their new employees and advance the skills of their already well-established workers.

This article explores how Chesterton leveraged VKS Enterprise software, which can also benefit the food & beverage sector, to create an innovative training program and effectively share knowledge across their workforce and continues at VKS.

Print this page