For both the A-Style and the K-Style diverter design option, the primary responsibility is to divert material from a single source toward either of two locations. However, the application benefits for each design vary from one another.

What do these diverters have in common?

In gravity flow applications, certain materials achieve optimal flow rates if they are processed through a diverter with steeper, more dramatic outlet leg angles. Steeper angles are used to flow heavier, denser materials – such as aggregates. Steep angles reduce the likelihood of in-line material build-up or material plugs, which can otherwise create the need for maintenance.

If a diverter has more subtle angles, material velocity will slow, causing materials to drag along the bottom of the valve as they flow. With steeper outlet angles, material is able to suspend and flow more freely through the channel. As a result, the valve makes little contact with materials and thus, is subjected to less wear and abrasion, which furthers the valve’s useful life.

A common misconception of diverter valves is that the blade can be shifted “on the fly” to divert material toward different locations as material flows through it. While the equipment does have the mechanical capabilities to do so, actuating a diverter in a continuous stream of material is harmful to the diverter’s functionality.

As the diverter actuates, materials can pack in areas where the blade comes in contact with the diverter body. Over time, material build-up may occur at these points, preventing the blade from properly sealing and allowing material leakage through the diverter.

Should a diverter need to be shifted to redirect material toward the other destination, a slide gate can be installed above the diverter to shut off material flow prior to re-positioning the blade.

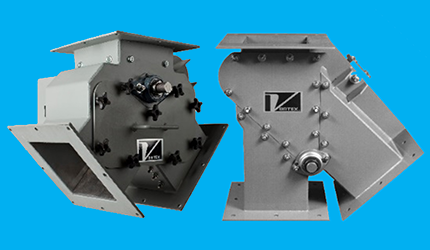

This article was provided by Vortex Global. Read more…

Print this page