3D printed diaphragm valves made for the pharmaceutical industry

Mike Edwards

News 3D printing additive manufacturing diaphragm valves KSB Group pharmaceutical industry SISTO Armaturen

KSB Group company SISTO Armaturen S.A., based in Echternach, Luxembourg, is the first valve manufacturer to supply series-produced additively manufactured (3D-printed) diaphragm valves made of a special alloyed material.

Delivery to one of Germany’s largest pharmaceutical companies commenced at the end of 2022.

Conventionally, valve bodies are machined from solid forged material. In this case, KSB says, the manufacturer relies on suitable forging bars being available, which may cause long delivery times, particularly for special materials.

Shorter delivery times can be realized with powder bed fusion, it adds. But this is only one of the benefits of valves manufactured using this method. It also enables geometries with undercuts, such as integrated cooling channels, which would not or hardly be possible using a milling process.

Body parts made by additive manufacturing are said to also have a higher material homogeneity. In addition, components designed for 3D printing are significantly lighter than conventionally manufactured components.

The suitability of additively manufactured materials has been tested and documented by the Luxembourg-based valve manufacturer in cooperation with the German TÜV. Additively manufactured diaphragm valves meet all standards governing their application, for example the requirements of the European Pressure Equipment Directive (PED) 2014/68/EU.

KSB SE & Co. KGaA, the parent company of SISTO Armaturen S.A., draws on more than ten years of experience in metal 3D printing and operates a technology centre for additive manufacturing at its Pegnitz site.

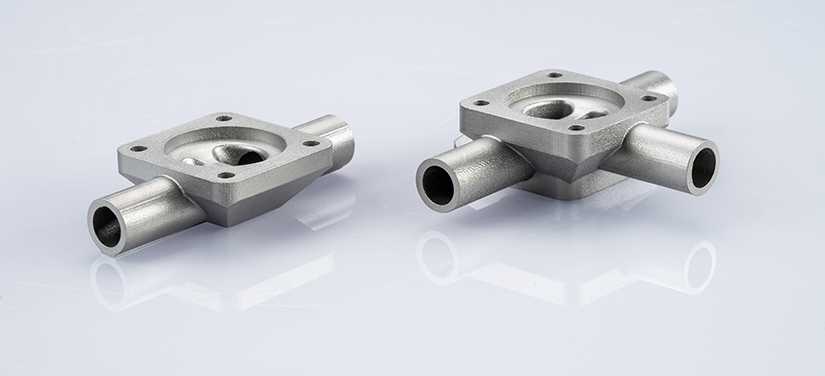

Above: 3D-printed multiway diaphragm valve bodies for the pharmaceutical industry, prior to surface treatment

Print this page