CMTS a showcase for Festo automation integration

Mike Edwards

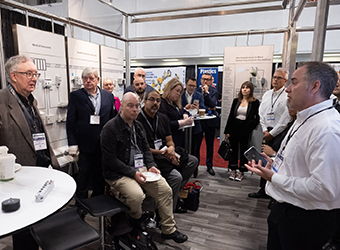

News festo software Festo product manager Darren O'Driscoll (right) answers questions from the press at CMTS 2019.

Festo product manager Darren O'Driscoll (right) answers questions from the press at CMTS 2019. Visitors to the Festo booth at last week’s Canadian Manufacturing Technology Show in Mississauga, ON, could actually touch some parts of the Festo automation platform, like the next generation CMMT-AS and CMMT-ST servo drives. It’s what they can’t touch that is taking automation projects to a new level of convenience, the company says.

The Festo platform is designed to be a holistic system for facilitating seamless, universal connectivity. The platform elements — an expanding portfolio of mechanical and electrical components, downloadable software and online configurators – are integrated and optimized to simplify and accelerate every aspect of an automation project, from planning and design through commissioning and even connection to the cloud. It makes automation more accessible, with major time- and cost savings, less risk and potentially a lot less aggravation.

The CMMT-AS and CMMT-ST servos displayed at the biennial CMTS exhibition can operate as standalone products or be paired with Festo or third-party motors. They can also be commissioned in literally minutes using the new, PC-based Festo Automation Suite software, another platform feature. With the free downloadable software, only five steps are needed to parameterize and configure all parts of a servo drive/motor closed loop installation using CMMT-AS and CMMT-ST drives, from the mechanical system to the system controller. The software is very intuitive, with a clean looking interface that’s easy to grasp and customize.

Festo’s new CMMT-AS and CMMT-ST perform exceedingly well as standalone servo drives, but as an integral part of the Festo automation platform, they can be commissioned in literally minutes using the new, PC-based Festo Automation Suite software.

For the expert user, a CMMT-AS plug-in for the Automation Suite software provides access to all device parameters to make advanced optimizations. Also, it allows the CMMT-AS to be integrated into the program of Festo’s CPX-E controller with just two clicks rather than the 100 or so it would take otherwise. Once the drive is paired on-screen with the controller, the integration of the necessary libraries and the linking of process data to the transfer of important axis parameters takes place automatically.

Another new Festo component on display at CMTS– the CPX-AP-I remote I/O control module – also has a plug-in that can be added to the Automation Suite software for fast, easy commissioning.

Besides the Automation Suite software, the roster of digital tools on the automation platform includes the proven Handling Guide Online for designing a Festo handling system in as little as 20 minutes, Festo Projects, which simplifies project planning and the lifecycle management of Festo components, and Festo Dashboards, for visualizing cloud-based data and supporting big data analytics. (When the Festo Motion Control Package is ordered along with a Festo handling system, the user gets a complete hardware and software package, usually in just a few weeks. It includes servo drives with safety circuit, power supply, gateway to the customer’s preferred fieldbus and circuit protection; all pre-assembled and pre-wired, tested and certified for fast start-up. Artesian motion applications can be configured and integrated quickly with function blocks or AOIs for various controller brands.)

Print this page