Controlling Your Natural Gas Burn to Cut Fuel Costs and Emissions

By Art Womack, Sr Application Engineer Fluid Components International (FCI)

Features News emissions gas ipptNearly all industrial processes and manufacturing operations rely on natural gas as a fuel, even if it is only for plant heating, ventilation and air conditioning (HVAC).

Heavy duty industrial plant processes (Figure 1), such as those found in oil and gas, refining, chemical production and electric power generation, as well as those in the manufacturing industries, including steel, aluminum, glass and others, depend heavily on natural gas to fuel the processes used in their production.

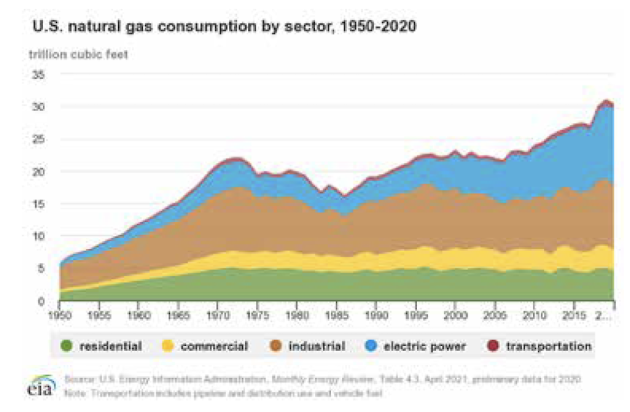

According to the U.S. Energy Information Agency (EIA) 1, in 2020 the U.S. consumed about 30.5 trillion cubic feet (TcF) of natural gas (or 31.5 quadrillion British Thermal Units (BTUs). The primary uses of natural gas in the U.S. is for electricity generation and industrial heating, with 38% for electric power generation followed closely at 33% for use by industry, 15% for residential, 10% for commercial, and 3% in transportation. Note that electric power’s share also includes the electricity consumed by industry.

Figure 2: U.S. natural gas consumption by sector in 2021.

“The industrial sector uses natural gas as a fuel for process heating, in combined heat and power systems, as a raw material (feedstock) to produce chemicals, fertilizer, and hydrogen, and as lease and plant fuel (Figure 2). In 2020, the industrial sector accounted for about 33% of total U.S. natural gas consumption, and natural gas was the source of about 34% of the U.S. industrial sector’s total energy consumption.” In addition, the U.S. EIA includes the natural gas used to move product through pipelines as a fuel separately under its transportation category.

The Challenges

The cost of natural gas for electric power and for industrial heating processes is expected to rise as access to supplies is reduced, while emissions controls also continue to grow more stringent. For these reasons, there is an urgent need for industrial process and manufacturing companies to optimize and more tightly control heating processes that involve burners, boilers, furnaces, ovens, kilns, dryers, oxidizers and flare stacks (as well as reduce their electric power costs).

Many process and plant engineers will be familiar with some form of the old adage, “You can’t control what you don’t measure accurately.” Fortunately, there are many process heating best practices that can be incorporated into industrial plant operations. The one thing all of these enhancements depend on, however, is accurate, consistent air/gas flow measurement to control the burn and assure highly efficient heating.

These best practices not only help manufacturers become leaner by saving money, but they also allow them to become industry leaders in green, sustainable practices. With the U.S. Securities and Exchange Commission (SEC) announcing recently its consideration of a new climate emissions disclosure rule that would affect public companies, the U.S. could soon join other European countries already measuring and reporting their carbon footprints. 2

Four Key Factors to Control the Burn

To reduce natural gas consumption, it is important that process and plant engineers know how to control the calorific value of their gas feed for any industrial heating process. To reach this goal, there are four key factors that engineers and technicians must consider when optimizing heating processes involving boilers, vessels, ovens, kilns, dryers, heaters, etc.

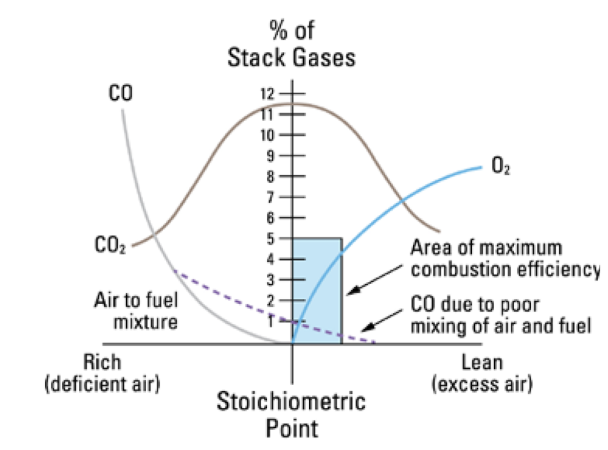

#1 Process Stoichiometric Burn Ratio

The stoichiometric point in well controlled natural gas fired processes is where the mixture of fuel to air is optimal. Too little air, and the burner fire doesn’t achieve its full calorimetric heating potential and natural gas is wasted when it takes longer than necessary to achieve and sustain the required heating levels for vessel burners or steam boilers (Figure 3).

Figure 3: Stoichiometric burn process.

When the fuel mixture is too air rich, then there is the potential for excess nitrogen oxide (NOx) emissions, which are a highly reactive gas and toxic pollutants. NOx often appears as a brownish gas (remember smog). It is a strong oxidizing agent and plays a major role in the atmospheric reactions with volatile organic compounds (VOC) that produce ozone on hot summer days.

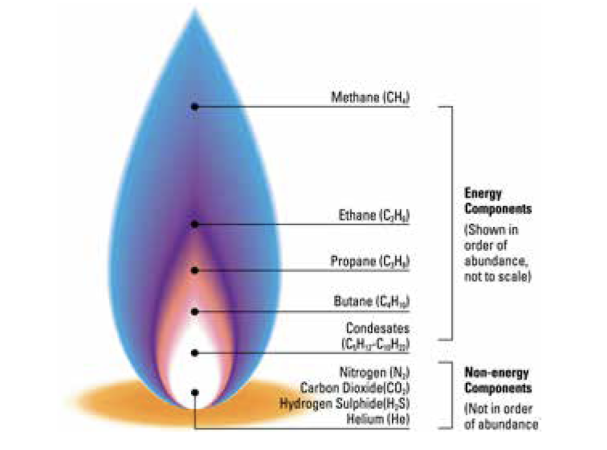

#2 Effects of Gas Composition

Natural gas composition (Figure 4) differs somewhat around the world, as well as seasonally in very cold winters and hot, humid summer conditions. The primary energy components of natural gas are methane, ethane, propane, butane and condensates. The non-energy components are nitrogen, carbon dioxide, hydrogen sulfide and helium.

Figure 4: Natural gas composition.

The mix of these components can affect gas density, the calorific value and then in turn plant instrumentation. Very few flow technologies are fully immune or easily adapt to changes in gas composition. A few volumetric flow technologies utilize a fixed gas density at ambient conditions, not taking into account pressures and temperatures that could affect mass flow readings. Some thermal flow instruments, however, are available with multiple calibration groups, which can automatically switch seasonally or any time as inline gas analyzers indicate changes in the gas mixture to assure the proper air/gas ratio is maintained for heating efficiency.

#3 Process Variability – Turndown Range

Continuous and batch processes often operate at variable levels of production, which means the amounts of natural gas and oxygen required for heating are also variable. Some of the reasons include processing multiple products on the same line, seasonal demand, wash-down cycles, seasonal planned maintenance, shift changes, etc.

For the most accurate gas and air flow measurement, a laboratory-like steady-state flow is generally the easiest to measure. That’s why in actual plant installations it is important to understand the potential full flow range of the gas to be measured, also known as turndown range – from the lowest to highest flows and if the flow measurement accuracy expected will be available over the entire flow range.

#4 Flow Meter Accuracy and Repeatability

In order to achieve the desired flow measurement accuracy level with confidence, the process or plant engineer must define the required process flow range, the desired flow measurement accuracy and the expected turndown ratio. For example, some processes require a rapid start-up with initially fast heating and then revert to a much lower steady- state or standby function in between batches. The speed of these changes in gas flow can affect measurement accuracy.

The major natural gas flow meter technologies available (Coriolis, differential pressure, thermal, ultrasonic, vortex) all vary in specified accuracy from a high of ± 0.01% or less depending on their turndown ranges from 1,000:1 to 8:1 (and depending on sensing where the higher cost is easily justified. Differential pressure, on the other hand, is a volumetric sensing technology typically used in liquids, which requires separate temperature and pressure compensation measurements to infer the mass flow rate of a gas.

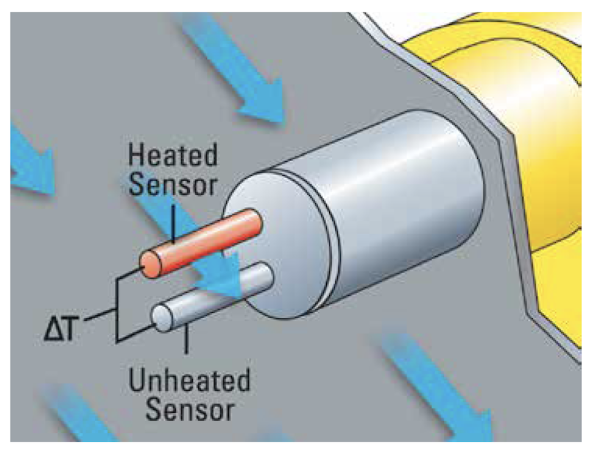

In comparison, direct mass flow thermal sensing technology places two thermowell protected platinum RTD temperature sensors in the process stream. One RTD is heated while the other senses the actual process temperature. When using the Constant Power method of driving the sensor, the temperature difference between the RTDs generates a voltage output, which is proportional to the media cooling effect for determining the gas mass flow rate (Figure 5) without extra pressure or temperature transmitters required by volumetric devices to account for changes in gas density.

Figure 5: Thermal dispersion flow sensing.

When measuring air or gas, a thermal flow meter is typically the simplest and least complicated solution. In many cases, an insertion type sensor can be used, which eliminates the need for costly bypasses required for servicing a spool piece flow element. There are no additional sensors or other electronics to purchase, install, and maintain, which can add to the total installed and lifecycle costs of an instrumentation purchase decision. These qualities speed instrument return-on-investment (ROI) too. In addition, there are no moving parts to break off for safety in natural gas pipes and no orifices to plug or foul requiring extra cleaning maintenance when recycling dirty gas for co-gen power applications.

Calibration Methodologies

When it comes to gas flow meters, it is important to ask the supplier about the type of calibration that will be performed. The industry relies on two standard calibration procedures: Air equivalency gas calibrations or laboratory gas calibrations performed under actual plant conditions. The equivalency method presumes that a substitute gas can be used in the calibration process. This methodology assumes that the thermo-physical properties of the substitute gas are similar to that of the actual gas to be measured; which is quite often not the case, especially when hydrocarbons and hydrogen are involved.

Figure 6: FCI calibration lab.

A laboratory calibration that best mirrors actual plant conditions will provide the best results. These calibrations will take into account conditions that can include variable flows, high and low temperatures, multiple gas compositions, etc. (Figure 6). The user is then presented with the calibration flow data recorded from the actual instrument calibration process that provides assurance the meter will operate accurately and dependably under installed field conditions.

Installations with Limited Footprints

When planning to optimize an existing natural gas process line, an early consideration should be the optimal location of the flow instrument. Today’s legacy process and manufacturing plants are often a dense maze of piping, instruments and equipment that make installing anything new a challenge. Flow meters installed to optimize natural gas heating processes are no exception.

All air/gas flow meters typically perform most accurately and consistently in a laboratory-like environment under a steady-state air/gas flow with no disturbances. In a real plant installation, they require a minimum upstream and downstream straight pipe run of several diameters away from obstacles such as elbows, valves and blowers to achieve a disturbance-free, measurable uniform flow profile. Without the required straight-run, accurate and dependable flow measurement can be problematic depending on the actual flow disturbances in the pipe.

Figure 9: FCI ST75 with built-in Vortab conditioner.

To simplify meter installation in space restricted areas of a plant, flow conditioners are available to tame unruly gas flows for proper measurement. For example, the FCI ST75 flow meter with its optional integral Vortab flow conditioner (Figure 7) solves these issues with its uniform mixing tabs that actually straighten the gas flow prior to measurement.

For larger lines, spool or plate designs can be utilized with single-point thermal mass flow meters, as well as other technologies. It is important to pay attention to how the flow conditioner performs. Be sure to properly address swirling flow conditions from elbows out-of-plane that could affect measurement performance. Also, look at permanent pressure loss for the type being used to avoid wasted energy costs.

Conclusions

With supply issues, rising prices and mandated carbon footprint measurement all on the horizon, the question is not whether to optimize your plant’s natural gas processes, but when is the time right to get better control of your burn. The higher gas prices go, whether because of supply, inflation or regulation, the faster the ROI payback on what is typically the modest cost of a flow meter upgrade to supporting better natural gas flow heating of your processes.

As you consider or plan the optimization of natural gas heating processes, you might want to consider the words of Rear Admiral Grace Murray Hopper, “The most dangerous phrase in the language is ‘We’ve always done it that way’.”

References

- US EIA Natural Gas Consumption, https://www.eia.gov/energyexplained/natural-gas/use-of-natural-gas.php

- Wall Street Journal, August 11, 2021, Page 1, 8, “Climate Accounting Looms for Companies”

Visit FCI online at www.FluidComponents.com | FCI is ISO 9001 and AS 9100 Certifi FCI World Headquarters, 1755 La Costa Meadows Drive | San Marcos, California 92078 USA

Phone: 760-744-6950 Toll Free (US): 800-854-1993

FCI Europe

Persephonestraat 3-01 | 5047 TT Tilburg, The Netherlands |

Phone: 31-13-5159989

FCI Measurement and Control Technology (Beijing) Co., LTD

Room 107, Xianfeng Building II, No.7 Kaituo Road, Shangdi

IT Industry Base, Haidian District | Beijing 100085, P. R. China

Phone: 86-10-82782381

Print this page