Regulator and air-actuated valve team up to eliminate pressure fluctuation at craft brewery

Mike Edwards

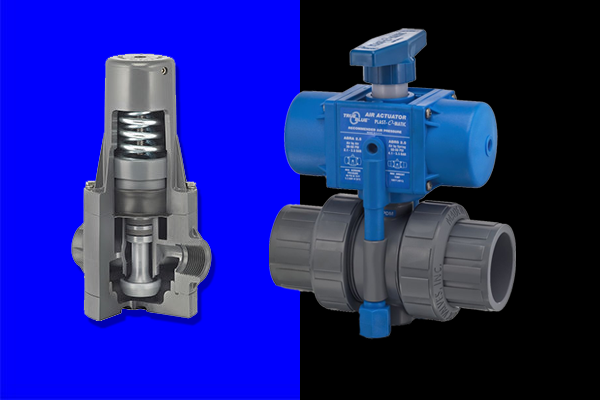

Features Craft brewery Plast-O-Matic video Plast-O-Matic PR pressure regulator (left) and ABRA ball valve were specified.

Plast-O-Matic PR pressure regulator (left) and ABRA ball valve were specified. With mid-sized and micro-breweries popping up all around the world, uneven water pressure and a never-ending variety of floorplans are creating headaches in the final rinse stations during the bottling and canning process.

A major U.S. brewery required a reliable method to supply multiple bottle rinse stations with a constant reverse osmosis (RO) water pressure. The challenge was to avoid varying pressures at one rinse station as other stations were turning on and off throughout the day.

Plast-O-Matic’s series PR pressure regulator was specified for its ability to convert varying inlet pressures (up to 150 psi) to a predetermined downstream (set) pressure, thereby conserving water and eliminating bottle breakage due to surging water pressure(s).

The series ABRA ball valve was also selected as the control shutoff valve due to its exceptionally long cycle life and modular design for ease of maintenance.

Usually, a final rinse of RO water ensures that any potential residue from the bottle cleaning and purification process will be removed before filling. It also rinses out any airborne particles that might detract from the intended flavour.

Problem is that fluctuating demand on other cleaning lines can result in overpressure as high as 150 psi/10.3 Bar that blows bottles off the line, or low pressure that fails to clean.

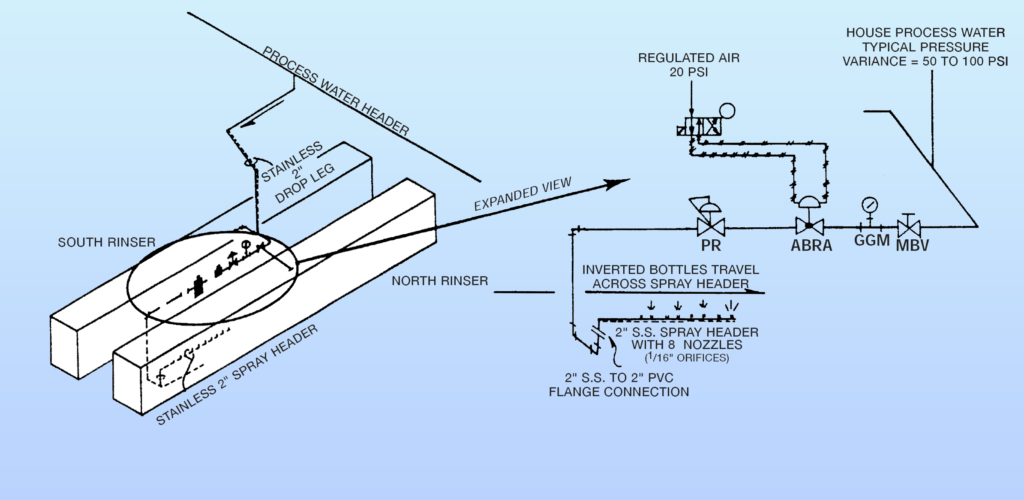

Brewery application bulletin schematic illustrates how Plast-O-Matic was able to provide rinse station spray nozzles with a consistent pressure.

By using a Plast-O-Matic Pressure Regulator and Air-Actuated Ball Valve at each rinse station, pressure can be maintained safely throughout the bottling operation. The regulator is an automatic, spring-controlled valve that converts varying inlet pressure to a constant, lower downstream pressure. By installing a regulator at each point of use, high pressure surges — and resulting drops elsewhere — are eliminated across the plant.

This type of rinse process isn’t limited to beverage bottling lines — packaging systems from healthcare to specialty chemical can also benefit from the same technology.

Watch video on how Pressure Regulators work:

To review this application, please click here.

Print this page