Tech Tips: Testing motors that have been stored should not be overlooked

Mike Edwards

Features All-Test PRO motor circuit analysis High humidity, moisture, dirt, dust, and vibration in a storage facility can negatively impact the insulation system of the motor.

High humidity, moisture, dirt, dust, and vibration in a storage facility can negatively impact the insulation system of the motor. One thing that is typically overlooked is how spare motors are stored. Over time, moisture, dirt, dust, and even general vibration from other sources can have a negative impact on the electrical and mechanical condition on the stored motors.

Stored motors should be periodically wiped down and cleaned to ensure proper functionality when the motor is installed.

The shaft of the motor should be periodically rotated to keep the grease inside the bearings from drying out or separating. It is recommended to rotate the shaft once a month but at a minimum the motor shaft should be rotated quarterly.

High humidity in a storage facility can also negatively impact the insulation system of the motor. Condensation can condense directly on the windings which will start to degrade the insulation material leading to premature motor failure once installed in the machine.

If the storage area does reach the dew point, heaters or dehumidifiers should be installed to prevent condensation.

Motor tags are an important component of storage. Motor tags should have general motor data, date of receipt in storage, and the storage maintenance requirements for the motor such as monthly or quarterly shaft turn, insulation, and resistance readings.

Other maintenance and measurement variables can be added to the tag depending on what criteria and test instrumentation the storage facility employs.

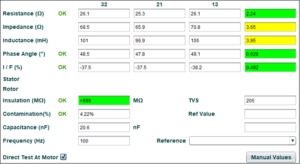

Before installation of the stored motor, All-Test Pro recommends performing a Motor Circuit Analysis (MCA) test to ensure winding degradation has not occurred while the motor has sat in the storage facility. This test can also be utilized as a baseline test that can be compared to and trended to in the future while the motor is in storage or after the spare motor has been installed.

Test Value Static (TVS) is a dimensionless number comprised of using a sub-set of the testing parameters of inductance, impedance (AC resistance), phase angle, and current-frequency ratio and scrubbing the resulting metrics with a complex algorithmic analysis.

Performing a motor circuit analysis after storage ensures that winding degradation has not occurred.

Any change in the TVS signifies a change in the motor windings, ground, rotor, cabling, etc. The initial test should indicate all three phases of the motor are symmetrical and do not indicate any contamination nor ground faults.

A TVS test value can be compared to future tests on the same motor and any deviation between the values signifies a change in the motor system due to a developing motor fault.

This article was contributed by All-Test Pro.

Print this page