Pneumatic cylinder designed just for cheese making

July 7, 2021

By Mike Edwards

The new cheese press cylinder from Festo improves control for greater consistency and quality in the pressing stage of cheese making.

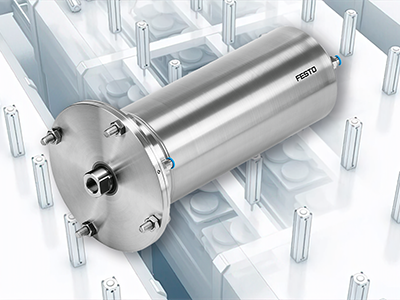

The new cheese press cylinder from Festo improves control for greater consistency and quality in the pressing stage of cheese making. Festo has introduced an application-specific pneumatic cylinder for cheese presses that improves consistency and quality in both large operations and low-volume artisanal cheese making. The stainless-steel outer body of the Festo CRD cylinder is said to represent the latest in sanitary innovation.

Its unique bell-shaped construction provides best-in-class hygienic design, according to Festo. These cylinders are lubricated with biodegradable NSF-H1 food-safe grease that meets FDA 21 CFT 172.878 regulations.

The CRD is available in four bore sizes, with forces ranging from 3,016 N to 18,850 N at 6 bar.

Watch video demonstration:

CRD cylinders are said to hold accurate pressure for the desired time to ensure precise process control, which optimizes product consistency and quality. To further enhance control, Festo offers the VTEM piezo operated directional valves to synchronize large banks of cylinders in automated systems.

Low-friction seals prolong service life. For environments experiencing intensive cleaning, Festo also offers CRD with a dry-running seal option for optimum operation even when harsh washdowns have dissolved cylinder lubricant.

To learn more about the new Pneumatic Cheese Press Cylinder (CRD), view the Cheese Press Cylinder brochure or email at food.processing.nam@festo.com.